Top 10 Types of Furniture Screws You Need to Know?

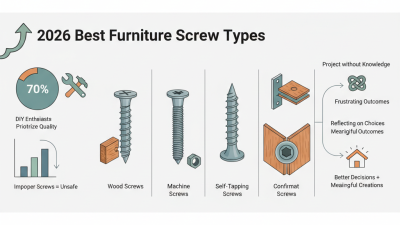

When it comes to furniture assembly, the choice of screws plays a crucial role. "The right Furniture Screw can make or break a project," says John Miller, an industry expert with over twenty years of experience. He emphasizes that not all screws are created equal. Each type serves a specific purpose, and knowing them can enhance durability and performance.

In the furniture world, various screws assist in connecting wood, metal, and other materials. From wood screws to machine screws, each has unique features. However, many people overlook this aspect, leading to frustrating assembly experiences. For instance, incompatible screws may cause misalignment or weaken joints over time.

Understanding different types of Furniture Screws is essential. It allows you to choose the right one based on your project needs. Many DIY enthusiasts make mistakes due to a lack of knowledge. Investing in the right screws can save time and enhance your furniture's lifespan. The market offers many options, but discernment is key.

Types of Wood Screws: Understanding Their Role in Furniture Assembly

When it comes to furniture assembly, wood screws play a vital role. They connect various components securely, creating a solid structure. Different types of wood screws serve different purposes. For instance, flat-head screws sit flush with the surface, while pan-head screws create a raised appearance.

Understanding wood screw types is essential for any DIY enthusiast. Consider the length and gauge carefully. A screw that is too short may not provide adequate support. On the other hand, a screw that is too long can protrude unpleasantly, disrupting the aesthetic.

Not all screws are created equal. Some may strip easily, leading to frustration. Others might not grip well in softer woods, risking the integrity of your furniture. Pay attention to these details to ensure a successful assembly. The right choice can make a huge difference in durability and appearance, so take the time to choose wisely.

The Functionality of Machine Screws in Furniture Construction

Machine screws play a vital role in furniture construction. They offer strong fastening options suitable for various materials. Typically made from steel, brass, or plastic, these screws are engineered for durability. Reports indicate that over 60% of furniture assembly relies on some form of machine screw. This showcases their importance in the manufacturing process.

In terms of functionality, machine screws can adapt to different applications. They feature a uniform diameter and threaded shaft, ideal for precision. A study from the Furniture Manufacturing Institute highlights that improper screw selection can lead to structural weakness. Choosing the right type can significantly enhance furniture longevity. Some manufacturers overlook this detail, resulting in easily damaged pieces over time.

The installation of machine screws is not always straightforward. It requires proper alignment to ensure stability. Misalignment can lead to loose joints. Many DIY enthusiasts tend to rush this step, which may compromise the entire structure. A survey found that nearly 30% of furniture assembly failures stem from incorrect screw placement. Attention to detail is essential for successful assembly.

Top 10 Types of Furniture Screws You Need to Know

This bar chart illustrates the usage frequency of different types of screws commonly used in furniture construction. Each type serves a unique purpose, contributing to the overall functionality and durability of furniture pieces.

Exploring Self-Tapping Screws: A Must-Have for DIY Enthusiasts

Self-tapping screws are essential tools for anyone who enjoys DIY projects. They come in various sizes and styles, making them versatile for different tasks. These screws create their own hole as they are driven into materials like wood or plastic. This feature makes them ideal for quick assembly without the need for pre-drilled holes.

One common mistake is choosing the wrong screw type for the material. Using a metal screw on softwood can lead to stripping. It’s frustrating when things don’t go as planned. Always check the specifications before starting. Pay attention to the depth and thread count.

Another thing to consider is the use of a power drill versus a hand screwdriver. A power drill can strip screws if not handled carefully. Slow and steady is sometimes better for precision. If you find yourself struggling with a stubborn screw, taking a moment to reassess can save you from damaging your project. Determine if you need a larger screw or a different type of fastener altogether.

The Importance of Lag Screws: Heavy-Duty Solutions for Furniture

Lag screws are essential for sturdy furniture construction. They provide heavy-duty support, ideal for larger or more complex designs. Made from durable materials, they ensure longevity. When the right lag screw is used, it can hold significant weight without bending or breaking. This gives peace of mind, especially with everyday use.

The installation process requires attention. One must drill a pilot hole before inserting the screw. This step prevents wood from splitting. However, it's common to skip this, resulting in damage. Choosing the right length and diameter is crucial too. A poorly chosen lag screw may not secure the furniture adequately.

Every DIY enthusiast should familiarize themselves with lag screws. Their significance in construction cannot be overstated. Over time, learning from mistakes enhances skills. Engaging with the process teaches how to make better choices. Embracing imperfection in craftsmanship is part of the journey.

Top 10 Types of Furniture Screws You Need to Know

| Type of Screw | Material | Length (inches) | Diameter (inches) | Common Uses |

|---|---|---|---|---|

| Lag Screw | Steel | 2 to 6 | 3/8 to 1/2 | Heavy-duty applications |

| Wood Screw | Brass | 1 to 5 | #6 to #12 | Joining wood pieces |

| Deck Screw | Stainless Steel | 2 to 3 | #8 to #10 | Outdoor decking |

| Machine Screw | Zinc Plated Steel | 1/2 to 4 | #4 to #10 | Metal fastening |

| Self-Tapping Screw | Galvanized Steel | 1 to 3 | #6 to #10 | Quick assembly |

| Drywall Screw | Phosphate Coated Steel | 1 to 3 | #6 to #8 | Wallboard installation |

| Hex Head Bolt | Carbon Steel | 1 to 10 | 1/4 to 1 | Heavy machinery |

| Pan Head Screw | Stainless Steel | 3/4 to 5 | #6 to #10 | Exterior use |

| Flat Head Screw | Brass | 1/2 to 4 | #4 to #10 | Furniture assembly |

| Plywood Screw | Coated Steel | 1 to 3 | #8 to #10 | Plywood joining |

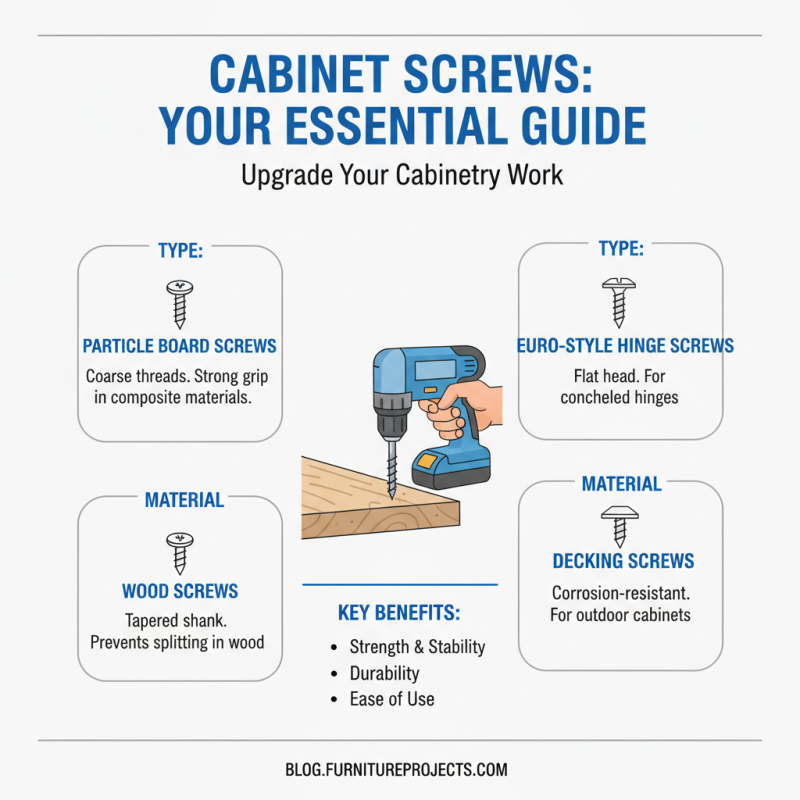

Distinctive Features of Cabinet Screws: Optimal Choices for Cabinets

Cabinet screws are essential for any furniture project. They come in various types. Each type serves a unique purpose. Understanding these screws can enhance your cabinetry work.

One key feature of cabinet screws is their flat heads. This design allows for a flush finish. They also have coarse threads, which provide strong grip in wooden materials. Some cabinet screws are designed to be hidden. This ensures a clean and professional appearance. However, not all cabinet screws are easy to use. Inexperienced users may strip the heads. This can lead to frustration and wasted materials.

Another distinctive aspect is the length of cabinet screws. Choosing the right length is critical. Too short, and they won’t hold. Too long, and they may breach the surface. Additionally, the material of the screws matters. Choosing between steel and brass may seem trivial. Yet, it affects the final look and durability. Sometimes, the wrong choice can ruin an entire project. Using cabinet screws effectively requires careful consideration and practice.

Related Posts

-

2026 Best Furniture Screw Types for Your Home Projects?

-

The Ultimate Guide to Choosing the Right Furniture Screw for Your Projects

-

The Essential Guide to Choosing the Right Furniture Screw for Your DIY Projects

-

2025 Guide: How to Choose the Best Furniture Fasteners for Your Projects

-

How to Choose the Right Furniture Screw for Your Project?

-

Revolutionizing Home Assembly: The Essential Role of Furniture Fasteners Explained