2026 Top Stainless Carriage Bolt Uses and Benefits?

Stainless Carriage Bolts are essential in various industries. They offer durability, corrosion resistance, and reliable fastening. According to John Smith, an industry expert, "Stainless Carriage Bolts enhance structural integrity in construction." These bolts are often used in projects where strength and longevity are crucial.

In the construction sector, the demand for Stainless Carriage Bolts is rising. Their applications range from securing wooden structures to metal fittings. With a smooth, rounded head and a square neck, they provide stability. Yet, some users still overlook proper installation methods. This oversight can lead to significant weaknesses in structures.

The benefits of Stainless Carriage Bolts often go unnoticed. While many recognize their quality, the specific advantages vary by use. In landscaping, for example, these bolts resist rust better than standard options. However, not using them correctly may diminish their effectiveness. Engaging with these details can help users appreciate their value more deeply.

Applications of Stainless Carriage Bolts in Construction Projects

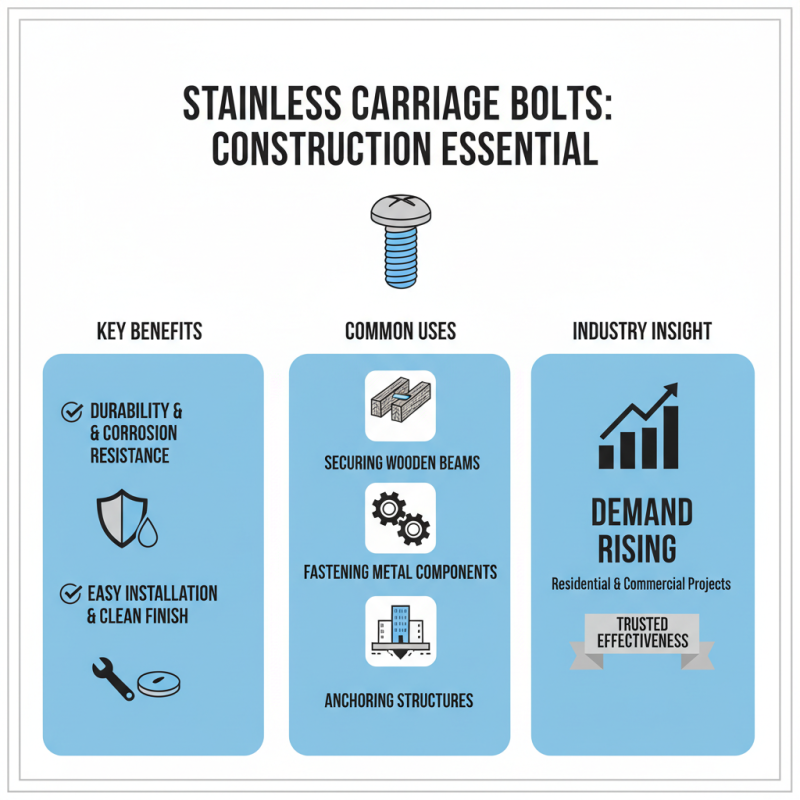

Stainless carriage bolts are essential in construction projects. They offer durability and resistance to corrosion, making them ideal for various applications. Their smooth, rounded heads allow for easy installation and a clean finish. In construction, these bolts are commonly used for securing wooden beams, fastening metal components, and anchoring structures. According to a recent industry report, the demand for stainless carriage bolts continues to rise due to their effectiveness in both residential and commercial projects.

Beyond their mechanical strength, stainless carriage bolts enhance a project's longevity. Their ability to withstand harsh environmental conditions makes them suitable for outdoor constructions. Many builders prefer these bolts to reduce maintenance costs over time. It's worth noting that improper installation can lead to structural issues. Ensuring that bolts are tightened to the specified torque can prevent potential failures.

Tips: Always inspect the bolt threads before use. Damaged threads can compromise the connection strength. Consider using a washer to distribute load evenly. This simple addition can improve stability. While stainless steel is robust, it’s crucial to select the right grade for your specific application. Choosing the wrong material can lead to unexpected corrosion.

Advantages of Using Stainless Steel Over Other Materials for Carriage Bolts

Stainless steel carriage bolts offer several advantages over traditional materials. Their corrosion resistance is particularly noteworthy. Exposed to moisture or harsh weather, they maintain structural integrity. Unlike carbon steel bolts, they do not rust easily. This makes them ideal for outdoor projects.

The strength-to-weight ratio of stainless steel also stands out. These bolts are surprisingly sturdy while remaining lightweight. This characteristic allows for easier installation. They can handle heavy loads without bending or breaking. It is crucial for safety in construction and automotive applications.

However, there are considerations. Stainless steel can be more expensive than other metals. This higher cost can pose budget challenges for some projects. Additionally, the installation process requires careful attention. Using inappropriate tools may lead to stripping or damage. It's a detail that shouldn't be overlooked.

2026 Top Stainless Carriage Bolt Uses and Benefits

This chart illustrates the various applications of stainless carriage bolts and their benefits in different industries. The data represents the percentage usage of stainless carriage bolts across five key sectors, showcasing their advantages over traditional materials.

Common Industries Employing Stainless Carriage Bolts and Their Benefits

Stainless carriage bolts play a vital role in various industries. They offer excellent corrosion resistance, making them ideal for outdoor applications. Manufacturers in construction rely on these bolts for securing steel to wood. This connection is crucial for structural integrity. The smooth, rounded head design prevents snagging, which can be a hazard on job sites.

In the automotive sector, stainless carriage bolts are used in assembly and repairs. They withstand harsh environments, including moisture and temperature fluctuations. This durability is essential for parts that endure significant stress and movement. Many marine industries also favor stainless options to prevent rust. This choice ensures longevity in saltwater conditions.

While stainless carriage bolts offer many benefits, some challenges exist. Sourcing high-quality fasteners can be tricky. Not every bolt meets the desired specifications. Moreover, the installation process requires careful attention to torque levels. Too much pressure can lead to material failure. Thus, understanding the correct application is crucial for achieving reliable results.

2026 Top Stainless Carriage Bolt Uses and Benefits

| Use Case | Common Industries | Key Benefits |

|---|---|---|

| Construction | Commercial Building, Residential | Corrosion resistance, Strength |

| Furniture Assembly | Home Furniture, Office Furniture | Aesthetic appeal, Durability |

| Automotive Manufacturing | Cars, Trucks | Vibration resistance, Weight savings |

| Marine Applications | Boats, Yachts | Rust resistance, Longevity |

| Heavy Machinery | Manufacturing, Construction | High load capacity, Reliability |

Best Practices for Installing and Maintaining Stainless Carriage Bolts

When installing stainless carriage bolts, proper techniques can make a notable difference. Begin by selecting the right drill bit. A pilot hole that matches the diameter of the bolt is essential. It helps to avoid splitting happens in the material. Ensure the surface is clean and free of contaminants. Dirty surfaces can lead to poor fittings.

Tightening is just as crucial. Use a wrench to grip the nut securely, but don’t over-tighten. This can weaken the joint and cause damage. Regularly check the bolts for looseness, especially in outdoor applications. Corrosion can also be a concern, even with stainless steel. Consider monitoring for rust or discoloration, which signifies wear over time.

Maintenance is key. Applying a lubricant can protect against corrosion and enhance performance. Inspecting the integrity of the bolts periodically will help in identifying issues early. This proactive approach can save time and money down the line. Everyone makes mistakes, but learning from them ensures a better outcome in future installations.

Factors to Consider When Choosing Stainless Carriage Bolts for Your Projects

When choosing stainless carriage bolts for your projects, several key factors come into play. First, consider the grade of stainless steel. Different grades offer varying levels of corrosion resistance. For outdoor projects, a higher grade like 316 is ideal. It withstands rust better than lower-grade options. However, it can be more expensive.

Always look at the bolt's diameter and length. Ensure it fits your specific application. A precise fit prevents structural weaknesses. You might need different sizes for different tasks. Keep in mind that not all bolts are created equal. You may find that the perfect size is out of reach. This can lead to frustrating delays.

Tips: Double-check your measurements before purchasing. It’s better to have the right size than to improvise later. Also, consider the head style. Some projects may require a specific type for easy installation. Beware of getting carried away with design. Sometimes simpler is better, even if it feels less impressive. Aim for functionality and strength.

Related Posts

-

7 Tips for Choosing the Right Button Head Bolt for Your Project

-

Ultimate Guide to Choosing the Right Button Head Bolt for Your Project

-

How to Select the Perfect Button Head Bolt for Optimal Load Distribution in Your Projects

-

How to Choose the Right Carriage Bolt for Your Next Project

-

How to Choose the Right High Tensile Carriage Bolt for Your Project Needs

-

Exploring the Benefits and Applications of Mushroom Head Carriage Bolts in Modern Construction