Ultimate Guide to Stainless Carriage Bolt Types and Usage Tips

In the world of construction and manufacturing, the Stainless Carriage Bolt is a staple. Its design affords strength and durability, making it ideal for various applications. Carriage bolts are unique due to their rounded heads and square shoulders, which prevent loosening. Understanding the different types of stainless carriage bolts can enhance the quality of your projects.

Selecting the right stainless carriage bolt is crucial for structural integrity. Factors like size, diameter, and material finish play significant roles in their effectiveness. Unfortunately, many people overlook these details. This can lead to failures that compromise the entire project.

Moreover, using stainless steel offers benefits like resistance to corrosion. However, the improper choice of bolt can diminish these benefits. A deep dive into the types available can reveal potential pitfalls and proper usage tips. As we explore these elements, remember that attention to detail is vital for achieving successful results.

Types of Stainless Carriage Bolts and Their Unique Features

Stainless carriage bolts are essential in various construction and repair projects. Understanding their types can help in choosing the right one for your needs. The most common types include A307, A325, and A490. Each type has unique features suited for specific applications. For instance, A307 bolts are often used in general construction. A325 bolts are designed for structural steel connections. A490 bolts are high-strength and used in critical applications.

When selecting a bolt, consider its tensile strength and corrosion resistance. The tensile strength of A325 bolts is typically around 120 ksi. This makes them suitable for heavy loads. In contrast, A307 bolts have a lower tensile strength, generally around 60 ksi. This lower strength may not be suitable for high-stress applications.

Tips for effective usage: Always match the bolt type to your specific project requirements. This helps avoid failures. Regularly inspect bolts for signs of wear or corrosion. Even stainless steel can corrode in certain conditions. If unsure, consult a professional. This step can save time and resources in the long run. Adopt a proactive maintenance approach to ensure the longevity of your installations.

Common Applications of Stainless Carriage Bolts in Various Industries

Stainless carriage bolts are essential in various industries. Their unique design makes them ideal for applications requiring a secure and stable fastening option. In the construction sector, they are widely used for connecting wood and metal structures. Reports indicate that nearly 40% of the fasteners used in construction are bolts.

In the automotive industry, stainless carriage bolts enhance durability. They resist corrosion, ensuring that vehicles remain safe over time. Many manufacturers prefer these bolts for chassis and suspension components, as they can withstand harsh environments. The industry sees a steady demand, with usage figures growing by 5% annually.

Tips: Always check the load capacity of carriage bolts before use. Using the right size is crucial for safety. Pay attention to the material; not all stainless steel offers the same protection against rust. In some cases, using incorrect fasteners can lead to structural failure.

Another key consideration is the torque applied during installation. Over-tightening can damage the fixation points. Reassessing the torque specifications can prevent costly repairs. Regular inspections of installed bolts are recommended to identify wear or loosening.

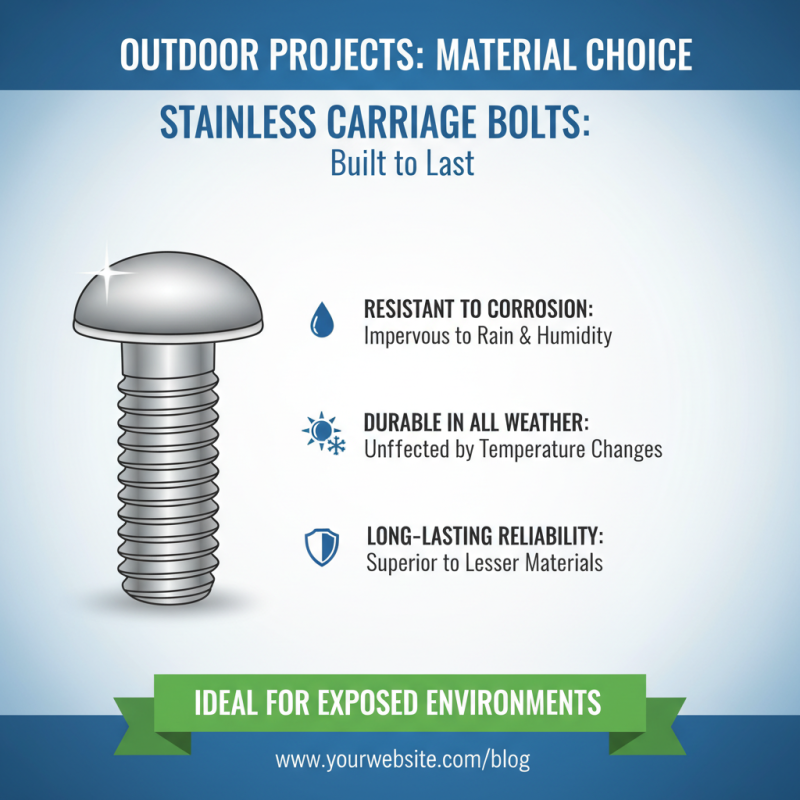

Benefits of Using Stainless Carriage Bolts in Outdoor Projects

When it comes to outdoor projects, the choice of materials is crucial. Stainless carriage bolts stand out for their durability and resistance to corrosion. This makes them ideal for use in exposed environments. Rain, humidity, and temperature changes can degrade lesser materials. With stainless steel, you get reliability over time.

Using stainless carriage bolts can enhance the longevity of your structures. These bolts can withstand harsh weather conditions without rusting. Imagine building a wooden deck or a garden bench. The last thing you want is for fasteners to fail due to rust. Stainless options ensure that your project looks great for years.

However, not every project requires stainless steel. The cost can be higher compared to standard bolts. For smaller, less critical tasks, a cheaper alternative might suffice. Be prepared to weigh the options carefully. Each project has its unique requirements. Sometimes, the most expensive choice isn't the best one.

Installation Techniques for Stainless Carriage Bolts: A Step-by-Step Guide

Installing stainless carriage bolts can seem tricky at first. A good foundation is essential. Gather your materials: bolts, washers, nuts, and a drill. Ensure the surface you’re working on is clean and stable. This makes a huge difference in the final result.

Begin by marking the holes where the bolts will go. Use a center punch for precision. It helps avoid drill slip. Drill pilot holes to guide your larger drill bit. This part is often overlooked but can lead to better alignment. Choose the right drill bit size; it’s key for a snug fit.

Insert the bolts from the underside of your surface. Ensure the head sits flush or just above the material. Add the washer and nut on top. Tighten slowly to avoid stripping. If the nut feels loose, reassess the installation technique. It’s easy to overlook the importance of checking everything as you go. Small mistakes can lead to significant issues later on.

Ultimate Guide to Stainless Carriage Bolt Types and Usage Tips

| Bolt Type | Diameter (inches) | Length (inches) | Material | Usage Tips |

|---|---|---|---|---|

| Standard Carriage Bolt | 1/4 | 2 | Stainless Steel | Use for securing wood to wood. |

| Square Neck Carriage Bolt | 5/16 | 3 | 304 Stainless Steel | Ideal for outdoor projects due to corrosion resistance. |

| Hex Head Carriage Bolt | 3/8 | 4 | 316 Stainless Steel | Best for high-strength applications; use with washers. |

| Slotted Carriage Bolt | 1/2 | 5 | Stainless Steel | Use for applications needing a flush finish. |

| Carriage Bolt with Round Head | 3/4 | 6 | Duplex Stainless Steel | Perfect for marine applications; highly resistant to rust. |

Best Practices for Choosing and Maintaining Stainless Carriage Bolts

When selecting stainless carriage bolts, consider the application. The right type can influence durability. Assess the environment where the bolts will be used. For outdoor projects, resistance to corrosion is crucial. Choosing A2 stainless steel works well for most applications. However, A4 grade offers better protection against saltwater.

Maintenance is vital for longevity. Regular inspections can prevent rust and ensure strength. Clean the bolts from dirt and debris to keep them in optimal condition. Sometimes, even stainless steel can exhibit signs of wear. Don’t ignore these issues. When bolts become loose, it could indicate a need for replacement. This reflection on usage can save future headaches.

Stainless Carriage Bolt Types Usage Overview

Related Posts

-

Top 10 Best Stainless Carriage Bolts for Your Projects

-

7 Best Tips for Choosing the Right Stainless Bolt for Your Project

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Innovative Trends in Truss Head Carriage Bolt Industry at 2025 China Import and Export Fair

-

2025 Top 5 Benefits of Using Mushroom Head Carriage Bolts for Your Projects

-

Top 10 Stainless Bolt Types for Maximum Durability and Performance in 2023