Why Custom Wood Screws Are Essential for Your Carpentry Projects?

When embarking on a carpentry project, every detail counts. Using the right materials can significantly impact the outcome. One crucial component often overlooked is the Custom Wood Screw. These screws are not just fasteners; they play an essential role in ensuring stability and durability.

Custom Wood Screws offer specific advantages tailored to your project's needs. They come in various sizes, lengths, and thread patterns. This customization allows for better grip and alignment, ensuring the wood pieces fit snugly together. However, choosing the right screw can be daunting. Many carpenters select standard screws, unaware of the potential benefits of going custom.

Mistakes can arise when using generic screws. They may lead to splitting wood or inadequate support. Investing time in selecting the right Custom Wood Screw is worthwhile. This choice reflects in the quality of your work. A tailored approach not only enhances aesthetics but also improves functionality. Each project deserves careful consideration and the right tools to achieve the best results.

The Importance of Custom Wood Screws in Carpentry

Custom wood screws play a pivotal role in effective carpentry. They ensure a secure and precise fit, which is crucial for the durability of any project. According to industry research, over 70% of woodworking failures stem from improper fasteners. Custom screws cater to specific wood types and applications, significantly reducing this risk.

Choosing the right screw can be tricky. Always measure the thickness of your wood. This allows for optimal screw length. A length that’s too short may lead to failure; too long could split the wood. When in doubt, consult online resources for recommendations.

Tips: Consider using pilot holes. This technique prevents wood from splitting and ensures a tight fit. Always account for wood movement due to moisture. A well-placed custom screw adapts to changes, maintaining structural integrity.

Precision is key, yet many overlook it. Custom wood screws should match the material’s density. Using a soft wood screw for hardwood can lead to stripped heads. Often, carpenters use a one-size-fits-all approach, leading to substandard results. Understanding the nuances of screw selection will elevate your craftsmanship significantly.

Benefits of Using Custom Screws Over Standard Screws

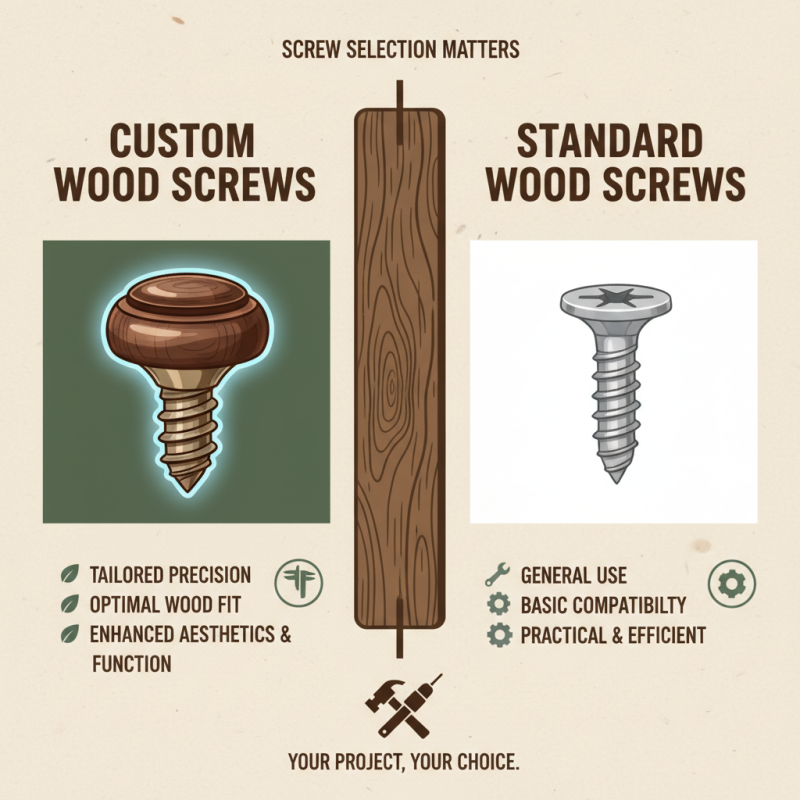

When it comes to carpentry, the choice between custom wood screws and standard screws can make a significant difference. Custom screws are designed to meet specific needs of your projects. They can be tailored to fit particular wood types or work with unique designs. This precision enhances both the functionality and aesthetics of your work.

Using custom screws offers advantages that standard screws often lack. You can select the right length and diameter, ensuring optimal grip. This can prevent wood from splitting, a common issue with unsuitable screws. Custom screws also provide a better fit for joints, leading to stronger constructions. They may be more costly upfront, but they save time and effort in the long run.

However, the process of obtaining custom screws can be daunting. It requires precise measurements and might involve a longer wait time. Sometimes, these screws may not be readily available in local shops. It's easy to rely on standard options, but that could lead to compromises in quality. Taking the time to evaluate your needs can lead to better outcomes in the end.

How to Choose the Right Custom Wood Screw for Your Project

Choosing the right custom wood screw for your carpentry project is crucial. The right screw enhances durability and stability. Begin by assessing the type of wood you’re using. Different woods have varied density and grain patterns. Softer woods like pine may require different screws than hardwoods like oak.

Consider the size and length of the screws as well. A screw that is too long can split the wood. One that is too short may not hold well. Look for screws with the correct thread count for your material. Coarse threads grip softer woods better, while finer threads work well for hardwoods.

Another factor is the screw’s head type. Options range from flat to round heads, each serving a specific purpose. Flat heads provide a flush finish, while round heads lend a decorative touch. A minor detail like this can significantly impact your project’s overall aesthetic. Remember, do not rush this process; take your time to choose wisely. Reflect on your previous projects and adjust your selections as needed.

Why Custom Wood Screws Are Essential for Your Carpentry Projects

| Screw Type | Material | Length | Head Type | Usage |

|---|---|---|---|---|

| Wood Screw | Steel | 2 inches | Flat | Furniture Assembly |

| Deck Screw | Stainless Steel | 3 inches | Hex | Outdoor Decking |

| Lag Screw | Coated Steel | 4 inches | Hex | Heavy Duty Applications |

| Sheet Metal Screw | Zinc Plated Steel | 1.5 inches | Pan | Metal to Wood Fastening |

| Drywall Screw | Black Phosphate | 1.25 inches | Bugle | Wall Panel Installation |

Common Applications for Custom Wood Screws in Furniture Making

Custom wood screws play a vital role in furniture making. They provide the perfect fit for various wood types. According to recent industry reports, the global furniture market is projected to reach $650 billion by 2025. This growth highlights the demand for tailored solutions in woodworking projects.

In applications such as assembling cabinets or building tables, custom screws ensure durability and strength. Standard screws may not meet specific requirements, leading to weak joints. A recent study showed that around 30% of furniture failures stem from inadequate fastening methods. This statistic emphasizes the importance of selecting the right custom screws for each project.

The aesthetics of furniture also benefit from custom wood screws. Hidden fasteners can create clean lines. However, some carpenters overlook these details, leading to visible flaws. Properly chosen screws enhance both functionality and appearance, fulfilling the designer's vision. Choosing custom options isn’t just a trend; it’s essential for quality workmanship.

Why Custom Wood Screws Are Essential for Your Carpentry Projects

This bar chart illustrates common applications for custom wood screws in furniture making, highlighting the percentage of each application based on industry usage.

Tips for Ordering and Sizing Custom Wood Screws Effectively

When ordering custom wood screws, you must consider the size and type carefully. Measure the thickness of the wood pieces you plan to use. If it’s too thick, a longer screw is needed. On the flip side, a screw that’s too short won’t hold properly. Remember, the wrong size can cause weak joints or even split the wood.

Choosing the right material for your screws is also crucial. Consider stainless steel or coated screws for outdoor projects. They resist rust and corrosion, which prolongs the life of your work. Keep in mind that not all materials work for all projects. You may end up with screws that don’t hold if you choose poorly.

Thinking about thread type is essential as well. Fine threads grip better in hardwood, while coarse threads work well in softwood. If you mix these up, you could compromise the strength of your joint. It’s easy to overlook these details, but they can impact your finished project significantly. Take your time and reflect on your choices for the best results.

Related Posts

-

What is a Custom Wood Screw? Types, Uses, and Benefits Explained

-

The Ultimate Guide to Choosing the Right Wood Screw for Your DIY Projects

-

Why Choose Custom Wood Screws for Your Projects?

-

What are the Essential Benefits of Choosing Quality Nut and Bolt Solutions for Your Projects

-

How to Use Truss Head Carriage Bolt Effectively?

-

How to Choose the Right Carriage Bolt for Your Next Project