Why Choose High Tensile Carriage Bolts for Your Projects?

In the world of construction and manufacturing, choosing the right materials is essential. High Tensile Carriage Bolts are increasingly popular. These bolts provide superior strength and durability. John Smith, an industry expert, once said, "High Tensile Carriage Bolts are the backbone of robust assemblies." This statement underscores their importance in project reliability.

High Tensile Carriage Bolts can withstand heavy loads and harsh conditions. Their design allows for easier installation and secure fastening. However, not all projects require these high-performance fasteners. Sometimes, traditional bolts might suffice, leading to potential cost savings. It’s worth considering the specific needs of each project before making a decision.

Incorporating High Tensile Carriage Bolts can enhance safety and longevity. Yet, it’s crucial to balance the benefits with project budgets. Experts often suggest evaluating if the added strength justifies the expense. Sometimes, projects face budget constraints. Reflecting on this balance can lead to more effective choices in material selection.

Benefits of Using High Tensile Carriage Bolts in Construction Projects

High tensile carriage bolts are essential in construction projects. They offer remarkable strength and durability. This makes them ideal for heavy-duty applications. Builders often prefer these bolts for securing wooden beams and metal structures. The ability to withstand large loads is a significant advantage. Unlike regular bolts, high tensile options resist shear stress better. This results in fewer failures during intense conditions.

Moreover, these bolts minimize the risks of structural damage. Their design allows for easy installation. Workers often find them easier to handle. However, proper torqueing is crucial. Incorrect installation may lead to bolts loosening over time. Observing this aspect can be a challenge on busy job sites. Therefore, it’s vital to conduct regular inspections. Ensuring that bolts maintain their integrity can prevent unforeseen issues.

Choosing high tensile carriage bolts also has a cost implication. They may be more expensive upfront. However, the long-term benefits often outweigh the initial investment. Fewer replacements can lead to overall savings. Additionally, using these bolts promotes safety for construction workers. Their robust nature helps to avoid catastrophic failures. Overall, high tensile carriage bolts are a smart choice for construction projects focused on durability and safety.

Comparative Analysis: High Tensile vs. Standard Carriage Bolts

When considering carriage bolts, the choice between high tensile and standard bolts can significantly impact your project. High tensile carriage bolts are made from stronger materials. They can withstand higher loads and resist deformation better than their standard counterparts. This strength is particularly valuable in demanding applications like construction or heavy machinery.

Tips: Always consult your project's load requirements. If you're unsure, it's better to choose high tensile options. They can provide peace of mind in structural integrity.

Standard carriage bolts may be suitable for lighter tasks. However, in situations where safety is crucial, compromising on strength isn't an option. A high tensile bolt can prevent costly failures. Consider the environment too; high tensile bolts are often more resistant to rust and corrosion.

Tips: Examine your materials closely. For projects in harsh conditions, consider coated options for added protection. Even small details matter when building durability.

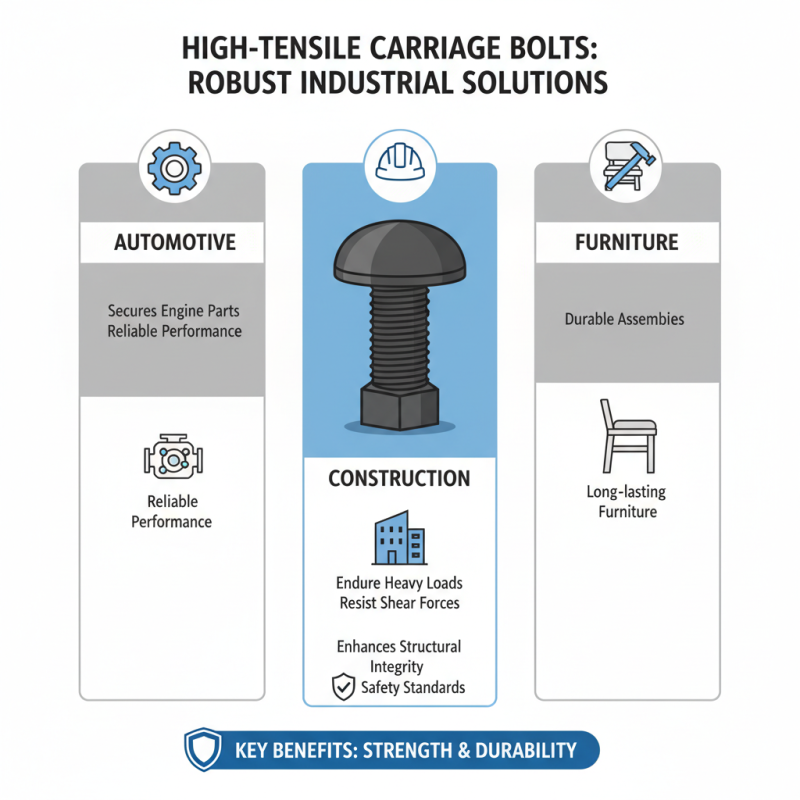

Applications of High Tensile Carriage Bolts in Various Industries

High tensile carriage bolts offer robust solutions across various industries. Their durability makes them essential in construction, automotive, and furniture manufacturing. For instance, in construction, these bolts follow specific safety standards. They endure heavy loads and resist shear forces effectively. This quality enhances structural integrity. In the automotive sector, they secure engine parts, ensuring reliable performance.

Tips: When selecting bolts, consider the load they must bear. Safety margins are crucial. Additionally, keep corrosion resistance in mind. It influences longevity significantly. Check if the coating meets your project's environmental conditions.

In furniture manufacturing, high tensile carriage bolts connect wooden pieces securely. They create strong joints, enhancing furniture stability. Designers appreciate their strength and versatility. However, improper installation can lead to issues. Misalignment may weaken the overall structure. Always double-check your work to avoid this.

In essence, high tensile carriage bolts find numerous applications. Understanding their uses promotes better decision-making in projects. Remember to assess project requirements carefully. Even a small oversight can lead to larger problems down the road.

Factors to Consider When Selecting High Tensile Carriage Bolts

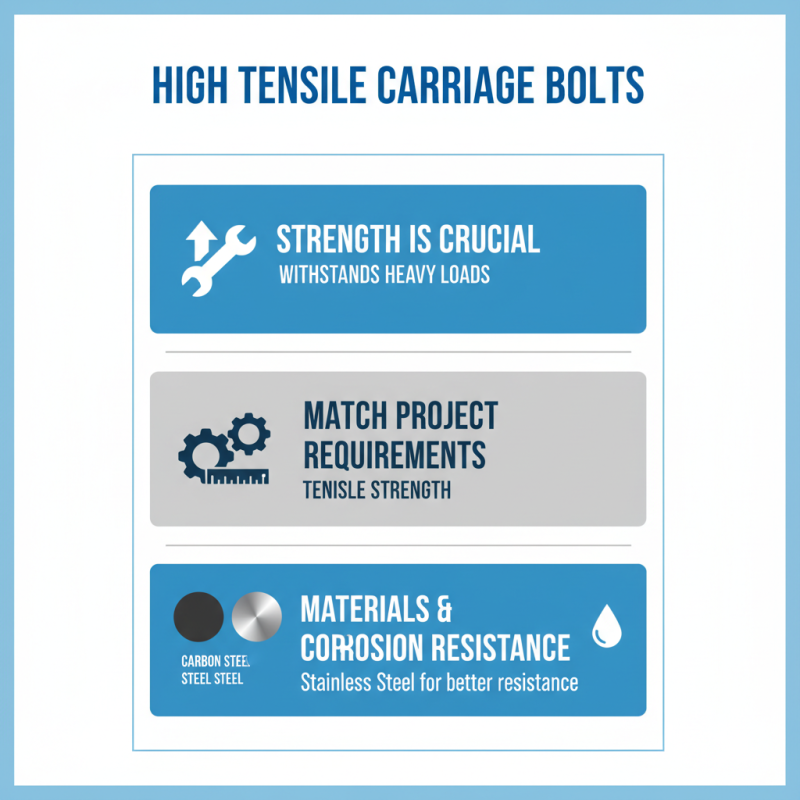

When selecting high tensile carriage bolts, strength is crucial. These bolts are designed to withstand heavy loads. Ensure that the tensile strength matches your project requirements. Consider the materials used. Carbon steel is common, but you might want stainless steel for better corrosion resistance.

Another factor is the bolt size and length. Make sure they align with your project's specifications. A mismatch can lead to project delays. Test a few before bulk purchase. Sometimes, dimensions can vary slightly among manufacturers. This small detail can affect performance significantly.

Lastly, think about the installation process. High tensile carriage bolts require specific tools. Do you have the right equipment? If not, that could complicate your project. Analyze your workspace too. Space constraints might limit how you use these bolts. Balancing strength, size, and ease of use is vital for project success.

Best Practices for Installing High Tensile Carriage Bolts Effectively

Installing high tensile carriage bolts requires attention to detail. Select the right drill bit for the material you’re working with. A mismatched drill can lead to damage and inefficiency. Ensure the hole is clean and free of debris. This simple step can drastically improve bolt installation.

When driving the bolts, don’t rush. Over-torquing can strip threads or break the bolt. Use a torque wrench for accuracy. If you notice any resistance, stop and check alignment. It’s better to adjust than to risk damaging your work. Sometimes, projects take longer than expected. Patience is key to achieving a strong and lasting connection.

Lastly, consider using washers. They distribute the load effectively, preventing bolt loosening over time. Even a small choice like this can make a significant difference. Reflect on your practices and improve with each project. Learning from small errors can lead to greater success in future tasks.

Why Choose High Tensile Carriage Bolts for Your Projects?

High tensile carriage bolts are essential for providing increased strength and durability in various construction projects. The chart above illustrates the significant material properties of high tensile carriage bolts, highlighting their tensile strength, yield strength, elongation, and hardness for effective performance.

Related Posts

-

What is a Hot Sale Carriage Bolt? Uses, Features, and Buying Guide

-

5 Essential Tips for Choosing the Right Truss Head Carriage Bolt for Your Project

-

Ultimate Guide to Choosing the Right Hot Sale Carriage Bolt for Your Projects

-

How to Choose the Right Carriage Bolt for Your Next Project

-

Innovative Trends in Truss Head Carriage Bolt Industry at 2025 China Import and Export Fair

-

Understanding the Importance of Carriage Bolt Selection in Construction Projects