Top 10 High Tensile Carriage Bolt Benefits and Uses for Your Projects

High Tensile Carriage Bolts are increasingly recognized as essential components in construction and manufacturing projects. According to industry reports, the global market for fasteners, which includes high tensile carriage bolts, is projected to reach USD 112 billion by 2025, driven by the escalating demand for durable and reliable fastening solutions. These bolts are designed to withstand high levels of tension and load, making them suitable for various applications, including construction, automotive, and machinery assembly.

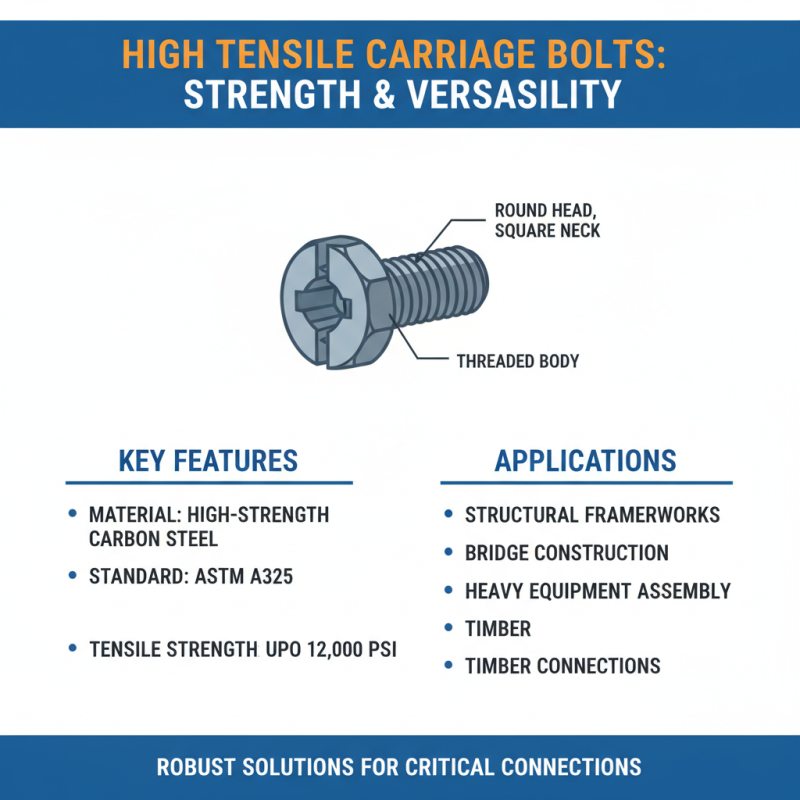

The benefits of using High Tensile Carriage Bolts extend beyond their impressive tensile strength. Their unique design, which features a rounded head and a square neck, allows for efficient fastening in wood and metal, preventing the bolt from turning when tightened. This characteristic is particularly valuable in dynamic environments where vibration can lead to loosening. Moreover, the ability of High Tensile Carriage Bolts to provide enhanced performance in high-stress applications demonstrates their importance in ensuring structural integrity and safety. As industries continue to prioritize quality and durability, the adoption of these bolts is likely to increase, solidifying their status as a preferred choice for engineers and builders alike.

Top Benefits of High Tensile Carriage Bolts in Construction Projects

High tensile carriage bolts are increasingly favored in construction projects due to their impressive strength and durability. These bolts are designed to withstand high levels of stress, making them ideal for heavy structural applications. Their ability to provide secure fastening in a variety of materials, especially wood and metal, ensures the integrity of constructions under varying loads and environmental conditions. This reliability minimizes the risk of structural failures, a critical concern for engineers and builders alike.

Additionally, high tensile carriage bolts offer excellent resistance to corrosion, particularly when coated or made from modern materials. This resistance makes them suitable for outdoor applications or in environments where exposure to moisture is prevalent. The ease of installation and the smooth, rounded head design also contribute to their convenience, allowing for a cleaner aesthetic and preventing snagging. This combination of strength, durability, and ease of use solidifies the importance of high tensile carriage bolts in modern construction projects, ensuring enhanced safety and longevity of structures.

Understanding the Material Properties of High Tensile Carriage Bolts

High tensile carriage bolts, made typically from medium carbon steel or alloy steel, are engineered for superior strength and durability. The tensile strength of these bolts can often exceed 1,000 MPa, making them ideal for applications that require a secure and resilient fastening solution. According to industry reports, high tensile carriage bolts are utilized extensively in construction, automotive, and heavy machinery sectors, largely due to their ability to withstand significant loads and resist shearing forces. This quality is particularly beneficial in structural applications where stability is crucial, such as in bridges and load-bearing frameworks.

Moreover, high tensile carriage bolts exhibit enhanced resistance to corrosion when coated or made from galvanized materials, making them suitable for exterior applications. Studies have shown that galvanized bolts can maintain their integrity in harsh environments, including those exposed to moisture and chemicals, thus extending the lifespan of engineering projects. The combination of strength and environmental resistance makes high tensile carriage bolts a preferred choice among engineers and contractors looking to ensure safety and longevity in their projects. The report by the American Fastener Manufacturers Association emphasizes that using high tensile fasteners can lead to fewer structural failures, ultimately reducing project costs in the long term.

Comparative Analysis: High Tensile vs. Standard Carriage Bolts

When comparing high tensile carriage bolts to standard carriage bolts, one must consider the varying compositions and mechanical properties that set them apart. High tensile carriage bolts are manufactured from stronger alloys and undergo more rigorous heat treatment processes, resulting in superior tensile strength. This makes them ideal for applications requiring enhanced durability and resistance to shear forces. In contrast, standard carriage bolts provide sufficient strength for lighter applications, but may not withstand the same level of stress or loading over time.

Another critical factor to assess is the impact of corrosion resistance in different environments. High tensile carriage bolts often come with advanced coatings or finishes that enhance their ability to resist rust and degradation, making them suitable for outdoor projects or in harsh conditions. Standard carriage bolts, while effective, may require additional protective treatments to ensure longevity in similar settings. Consequently, the choice between high tensile and standard carriage bolts should be informed by the specific requirements of the project at hand, considering factors such as load capacity, environmental exposure, and overall structural integrity.

Another critical factor to assess is the impact of corrosion resistance in different environments. High tensile carriage bolts often come with advanced coatings or finishes that enhance their ability to resist rust and degradation, making them suitable for outdoor projects or in harsh conditions. Standard carriage bolts, while effective, may require additional protective treatments to ensure longevity in similar settings. Consequently, the choice between high tensile and standard carriage bolts should be informed by the specific requirements of the project at hand, considering factors such as load capacity, environmental exposure, and overall structural integrity.

Common Applications of High Tensile Carriage Bolts in Various Industries

High tensile carriage bolts are widely recognized for their remarkable strength and versatility, making them an essential component in multiple industries. Their unique design, featuring a rounded head and square neck, allows for easy installation and resistance to loosening under torque. According to a report by the Fastener Quality Act, high tensile fasteners, including carriage bolts, can increase structural integrity by as much as 30%, significantly enhancing the durability of various applications.

In the construction industry, high tensile carriage bolts are often employed in timber framing, providing sturdy connections for beams and columns. A study by the Wood Products Council highlights that the use of high tensile carriage bolts can lead to increased load capacity in wooden structures, making them indispensable for building codes that emphasize safety and reliability. Additionally, in the automotive sector, these bolts are critical in securing body panels and undercarriage components, contributing to the overall strength and performance of vehicles. Reports indicate that high tensile fasteners help improve the life cycle of automotive assemblies by resisting fatigue and corrosion, thereby supporting the industry's shift towards more sustainable manufacturing practices.

Top 10 High Tensile Carriage Bolt Benefits and Uses for Your Projects

| Benefit/Use | Description | Common Applications | Industry |

|---|---|---|---|

| High Strength | Offers superior tensile strength, making it ideal for heavy-duty applications. | Structural connections in buildings | Construction |

| Durability | Resistant to rust and corrosion, enhancing lifespan. | Outdoor furniture and fixtures | Manufacturing |

| Ease of Use | Simplified installation process with a square neck that prevents spinning. | DIY woodworking projects | Construction |

| Versatile Lengths | Available in multiple lengths, suitable for various applications. | Furniture assembly | Furniture |

| Cost-Effective | Provides a strong solution at a lower cost compared to alternatives. | Bridge construction | Infrastructure |

| High Load Capacity | Designed to withstand significant loads and stress. | Heavy machinery assembly | Manufacturing |

| Prevents Pull-Out | Square neck design helps to resist pull-out forces. | Construction of wooden structures | Carpentry |

| Aesthetic Appeal | Can be used in visible parts of a project for a cleaner look. | Decorative woodworking | Interior Design |

| Wide Availability | Easily sourced from various suppliers and manufacturers. | General construction needs | Construction |

| Compatibility | Can be used with various materials, including wood and metal. | Mechanics and automotive applications | Automotive |

Industry Standards and Specifications for High Tensile Carriage Bolts

High tensile carriage bolts are increasingly recognized for their robustness and versatility in various construction projects. Industry standards stipulate that these bolts, typically made from high-strength carbon steel, conform to the ASTM A325 specifications for structural applications. Their high tensile strength, which can reach up to 120,000 psi, makes them ideal for applications requiring significant load-bearing capabilities. This strength is essential in circumstances where short-term and long-term loading conditions can impact the overall stability of structures.

The International Organization for Standardization (ISO) has also established standards for high tensile carriage bolts, categorizing them according to grades based on yield strength and tensile strength. For instance, ISO 898-1 delineates specific mechanical property requirements for fasteners, ensuring that high tensile carriage bolts maintain their integrity under dynamic loads. Furthermore, recent industry reports indicate a growing trend in the use of galvanized and coated bolts, which enhances corrosion resistance and extends the lifespan of these fasteners in outdoor environments, particularly in construction and infrastructure projects. The adherence to these standards ensures safety, reliability, and performance, making high tensile carriage bolts a preferred choice for engineers and contractors worldwide.

Related Posts

-

How to Select the Perfect Button Head Bolt for Optimal Load Distribution in Your Projects

-

7 Tips for Choosing the Right Button Head Bolt for Your Project

-

Ultimate Guide to Choosing the Right Button Head Bolt for Your Project

-

How to Choose the Right High Tensile Carriage Bolt for Your Project Needs

-

Innovative Trends in Truss Head Carriage Bolt Industry at 2025 China Import and Export Fair

-

2025 Top 5 Benefits of Using Mushroom Head Carriage Bolts for Your Projects