Ultimate Guide to Stainless Torx Screws Tips for Optimal Performance and Use

When it comes to securing materials with precision and durability, stainless Torx screws stand out as a top choice for various applications. These specialized fasteners feature a unique star-shaped drive that allows for enhanced grip, reducing the chances of cam-out during installation. This makes stainless Torx screws particularly advantageous in environments where reliability and performance are paramount.

In this ultimate guide, we will delve into the vital aspects of stainless Torx screws, offering tips and insights for optimal performance and use. From understanding their unique design features to exploring the various benefits they offer over traditional screw types, this guide is designed to equip you with the knowledge needed to make the most of these versatile fasteners. By the end, you will be well-prepared to select, install, and maintain stainless Torx screws effectively, ensuring that your projects are executed with the highest standards of quality and precision.

Understanding Stainless Torx Screws: Composition and Benefits

Stainless Torx screws are engineered from

high-grade stainless steel, providing exceptional corrosion resistance, strength, and durability. The

composition typically includes both chromium and

nickel, which enhance the material's ability to

withstand various environmental conditions, including moisture and chemicals. According to a report

from the International Stainless Steel Forum, stainless

steel's corrosion resistance is primarily due to the formation of a passive oxide layer, which

effectively protects the metal beneath. This makes stainless Torx screws an ideal choice for

outdoor applications where rust and degradation can compromise structural integrity.

The benefits of using stainless Torx screws extend beyond mere resistance to rust. Their unique design,

characterized by a star-shaped socket, allows for a better grip and increased torque application

compared to traditional screw heads. This design minimizes the likelihood of cam-out,

a common issue that can lead to stripped screw heads and ineffective fastening. A study by the

Fastener Quality Act suggests that utilizing specialized screws

like Torx can enhance assembly efficiency, leading to an increase in overall productivity by as much

as 30%. This not only simplifies assembly processes but also

promotes long-term reliability in various applications, from automotive industries to construction projects.

Key Features of Stainless Torx Screws for Enhanced Performance

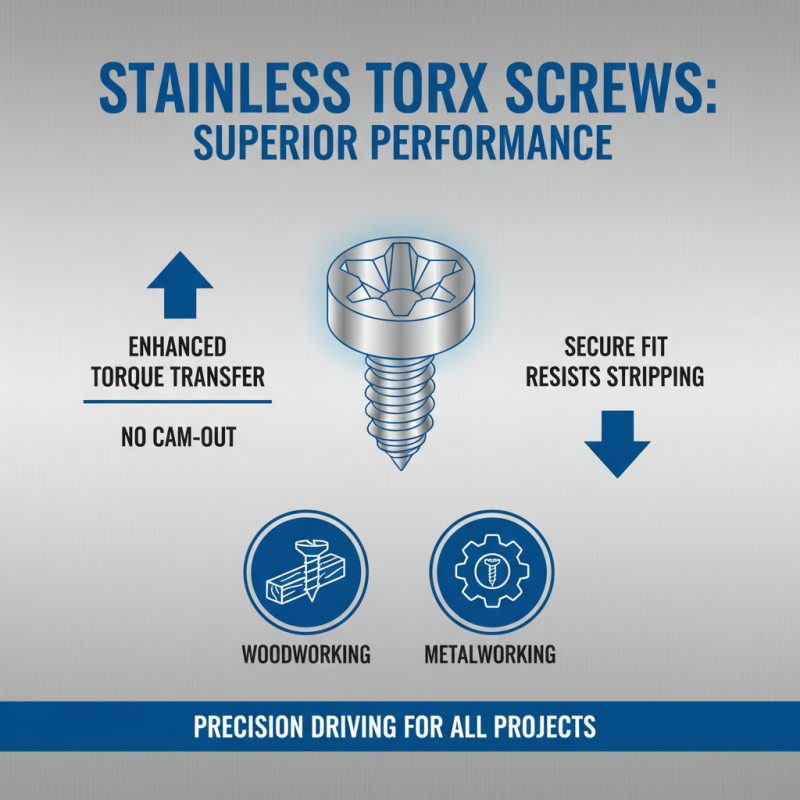

Stainless Torx screws are increasingly recognized for their superior performance in a variety of applications. One of their key features is the unique Torx drive design, which allows for enhanced torque transfer, reducing the risk of cam-out during installation. This feature not only facilitates a more secure fit but also ensures that the screws can withstand significant tightening without stripping. The precision of the Torx pattern makes it easier to drive screws into materials, making them an ideal choice for both woodworking and metalworking projects.

Another significant advantage of stainless Torx screws is their resistance to corrosion. Made from stainless steel, these screws are designed to endure harsh environmental conditions, making them perfect for outdoor use or in environments with high humidity. This corrosion resistance prolongs the lifespan of the screws while maintaining their structural integrity. Furthermore, many stainless Torx screws come with various coatings that can enhance their durability even further, making them suitable for various industrial applications where longevity is critical.

Overall, the combination of the innovative Torx drive design and the inherent properties of stainless steel makes these screws an excellent choice for anyone looking to improve the performance and reliability of their fastening solutions.

Choosing the Right Size and Type of Torx Screws for Your Project

When selecting the right size and type of Torx screws for your project, there are several key factors to consider. Torx screws, known for their star-shaped drive, provide superior torque and reduce the risk of stripping, making them ideal for applications requiring a secure fit. According to industry data from the Fastener Technology International magazine, the use of Torx screws can enhance load distribution, which is particularly beneficial in high-stress environments such as automotive and construction applications.

The size of the Torx screw is crucial to its performance. The screw should fit snugly into the drive without wobbling, which can lead to inadequate fastening or damage to the material. The American National Standards Institute (ANSI) outlines standard sizes for Torx screws, typically ranging from T1 to T100, allowing users to select the appropriate size based on their specific needs. Additionally, the choice between standard and tamper-resistant Torx screws can also influence project outcomes. Tamper-resistant options, often featuring a pin in the center, provide additional security to prevent unauthorized disassembly in critical applications.

Furthermore, consider the material of the Torx screws. Stainless steel is a popular choice for its corrosion resistance and durability, especially in outdoor or moisture-prone environments. A report by the Global Fastener Alliance highlights that the rise in demand for stainless screws has grown by approximately 15% annually due to increased awareness of their performance benefits. Therefore, choosing the right Torx screw size, type, and material can significantly impact the efficiency and durability of your project.

Best Practices for Installing and Maintaining Stainless Torx Screws

When it comes to installing stainless Torx screws, achieving optimal performance starts with proper preparation. Before any installation, ensure that the materials being joined are clean and free from any debris or dust that could interfere with the screw’s grip. Using a torque wrench not only prevents over-tightening, which can strip the screw or damage the material, but also assures consistent fastening across multiple installations. For best results, selecting the right length and size of Torx screw for the specific application is critical, as this affects load distribution and strength.

Maintenance is equally vital for the longevity and efficiency of stainless Torx screws. Regularly inspect the screws for signs of corrosion, wear, or loosening, especially in harsh environments. If rust or corrosion is detected, immediately address the issue to prevent structural failures. Additionally, applying a light coat of anti-seize lubricant can enhance their performance, particularly in applications involving high heat or moisture. By adhering to these best practices, you can maximize the life and functionality of stainless Torx screws in your projects.

Performance Analysis of Stainless Torx Screws

This chart illustrates the optimal torque specifications for various sizes of stainless Torx screws. Proper torque application is essential for achieving the best performance and preventing damage during installation.

Common Applications and Industry Uses of Stainless Torx Screws

Stainless Torx screws are increasingly favored across various industries due to their unique design and functional advantages. The star-shaped head allows for a better grip with the driving tool, reducing the likelihood of slippage during installation. This characteristic makes them particularly suitable for applications that demand a high level of torque, such as automotive assembly and aerospace manufacturing. Their resistance to corrosion further enhances their utility in environments exposed to moisture and chemicals, such as marine applications and outdoor structures.

In addition to their mechanical advantages, stainless Torx screws are commonly used in the construction industry for secure fixtures in wood, metal, and plastic applications. They excel in building decking, siding, and roofing where longevity and durability are crucial. Furthermore, their aesthetic appeal means they are also sought after in furniture manufacturing, where visible fasteners need to maintain a polished appearance while ensuring structural integrity. These screws not only provide function but also enhance the overall visual appeal of the product, making them a preferred choice for designers and builders alike.

Ultimate Guide to Stainless Torx Screws Tips for Optimal Performance and Use - Common Applications and Industry Uses of Stainless Torx Screws

| Application | Industry | Material Compatibility | Common Sizes | Advantages |

|---|---|---|---|---|

| Furniture Assembly | Furniture Manufacturing | Wood, Metal | #8, #10 | Corrosion Resistance |

| Automotive Assembly | Automotive | Steel, Aluminum | M5, M6 | Enhanced Torque Control |

| Construction Fastening | Construction | Concrete, Steel | #12, #14 | Reduced Stripping |

| Marine Applications | Marine | Stainless Steel | #6, #8 | Long-lasting Performance |

| Electronics Assembly | Electronics | Plastic, Metal | M2, M3 | Precision Fit |

Related Posts

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project

-

Top 10 High Tensile Carriage Bolt Uses Benefits and Buying Guide

-

7 Tips for Choosing the Right Button Head Bolt for Your Project

-

Understanding the Importance of Carriage Bolt Selection in Construction Projects

-

Exploring the Growth of Torx Screw Demand at the 138th Canton Fair China 2025: Insights and Trends

-

2025 Guide: How to Choose the Best Furniture Fasteners for Your Projects