10 Essential Tips for Choosing the Right Furniture Screws for Your Projects

When embarking on a furniture project, the choice of the right furniture screw can significantly impact both the durability and aesthetics of your final product. Industry expert John Smith, a seasoned carpenter and furniture building coach, emphasizes, "Choosing the correct furniture screw is the foundation of any proficient assembly; it ensures longevity and stability." With countless options available, understanding the various types, materials, and sizes of furniture screws is essential for both novice enthusiasts and seasoned professionals alike.

In this guide, we will explore ten essential tips that will help you navigate the intricate world of furniture screws. These insights will not only clarify the importance of selecting the right screws for specific applications but also shed light on how the wrong choice can lead to costly repairs and diminished functionality. Whether you're crafting a bespoke piece or simply repairing an existing item, knowing how to choose the right furniture screw can elevate your craftsmanship and ensure that your projects stand the test of time.

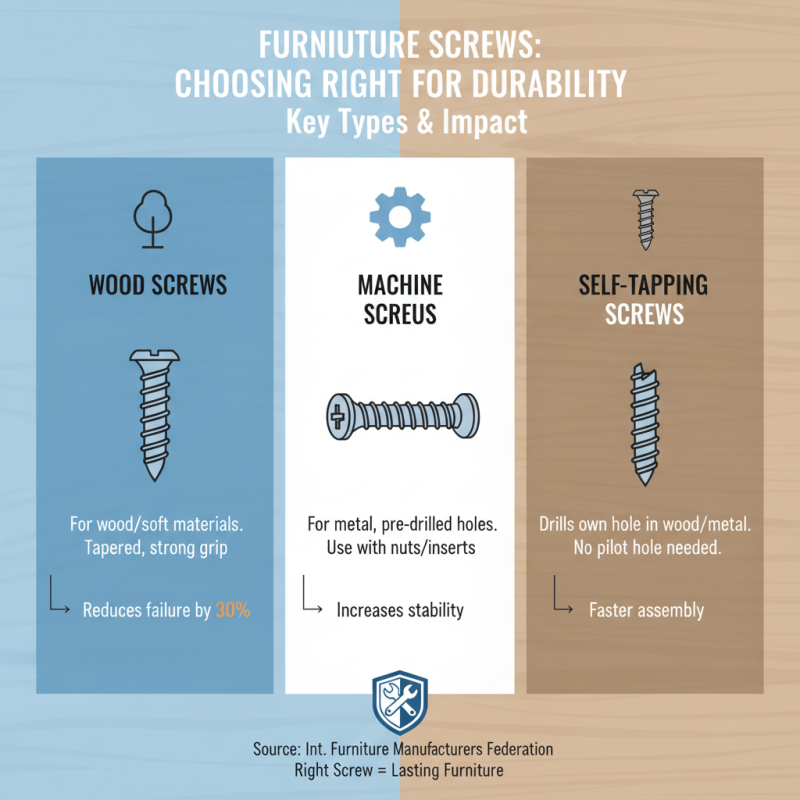

Understanding Different Types of Furniture Screws and Their Uses

When it comes to furniture assembly, the selection of screws can significantly impact the durability and functionality of your projects. Understanding the various types of furniture screws is essential for both DIY enthusiasts and professional woodworkers. Common types include wood screws, machine screws, and self-tapping screws, each designed for specific applications. According to a report by the International Furniture Manufacturers Federation, the correct choice of screws can reduce furniture failure rates by up to 30%, highlighting the importance of selecting the right type for your needs.

Tips for choosing the right screws include assessing the material of your furniture. For wooden projects, using wood screws with a sharp point and threaded body ensures a secure fit. Machine screws, often used with nuts and washers, are ideal for metal assembly, providing a strong hold in high-stress environments. Self-tapping screws are perfect for quick, efficient assembly in softer materials, allowing for faster project completion without pre-drilling.

Additionally, it is crucial to consider screw length and diameter based on the thickness of the materials you are joining. Using screws that are too short can lead to weak joints, while excessively long screws may protrude or split the material. Industry studies suggest that selecting the appropriate dimensions can enhance joint strength by as much as 50%, ensuring your finished projects are safe and robust.

Factors to Consider When Selecting Furniture Screws for Specific Projects

When selecting furniture screws for specific projects, there are several key factors to consider to ensure that you achieve a durable and reliable result. First, the material of the screw plays a crucial role. For instance, if your project involves wet or outdoor environments, rust-resistant screws such as stainless steel or coated screws are ideal. On the other hand, for indoor furniture, standard steel screws can suffice, provided that they are appropriate for the selected wood type.

Another important consideration is the screw length and diameter. The screws should penetrate deep enough into the material without splitting the wood. A good rule of thumb is to use screws that are at least twice the thickness of the materials you are joining. Additionally, the head type of the screw should match your tools and aesthetic preferences; flathead screws are excellent for flush finishes, while roundhead screws can add a decorative touch.

When tackling different projects, remember that pre-drilling may be necessary for hardwoods to prevent splitting. Always keep an eye on the load requirements of your furniture—heavier pieces will benefit from larger, sturdier screws. Utilizing these tips will not only enhance the strength of your assembly but also extend the life of your furniture.

How to Determine the Right Length and Diameter of Furniture Screws

When selecting the right length and diameter for furniture screws, it’s essential to consider the specific materials you will be working with. Typically, the screw should penetrate at least half the thickness of the material being joined to ensure a strong hold. For example, if you’re working with a piece of wood that is 1 inch thick, a screw length of at least 1.5 inches would provide optimal anchorage. Always ensure that the screw length is appropriate for both materials involved in the connection to avoid splits or insufficient hold.

When it comes to diameter, thicker screws usually provide more strength but require pre-drilling to avoid splitting the material. A good rule of thumb is to choose a screw diameter that is roughly 1/8 inch smaller than the thickness of the material being connected. This balance will give you the necessary strength while allowing for proper installation without damaging the pieces.

Tip: Always use a test piece when working with new materials or configurations. This way, you can determine the best screw sizes without risking damage to your final project. Additionally, consider using screws with deeper threads for enhanced grip, especially in softer woods. This can prevent the screw from loosening over time, ensuring the longevity of your furniture.

Materials and Coatings: Choosing the Best Screws for Durability

When selecting furniture screws, the choice of materials and coatings is pivotal for ensuring durability and strength in your projects. Screws can be made from various metals, but stainless steel and hardened steel are often favored for their resistance to corrosion and wear. If your project will be exposed to moisture, such as outdoor furniture or items in humid environments, consider screws with a weather-resistant coating. These coatings not only enhance corrosion resistance but also improve the overall lifespan of your furniture.

Tip: Always match the screw material to your project’s environment. For example, use brass screws in non-corrosive environments, while opting for coated screws in more challenging conditions to prevent rusting and degradation over time.

Additionally, consider the thread type and length of screws as these can significantly impact their hold. Coarse threads are better for softwoods, while finer threads work well in hardwoods and provide a tighter grip. Choosing the right length will help ensure that screws penetrate sufficiently without risking damage to the material they’re being driven into.

Tip: Before purchasing, test a screw in your chosen material to assess the fit and hold. This can prevent structural issues and ensure that your project withstands the test of time.

10 Essential Tips for Choosing the Right Furniture Screws for Your Projects

| Screw Type | Material | Coating | Durability | Best Application |

|---|---|---|---|---|

| Wood Screws | Steel | Zinc Plated | High | Furniture Assembly |

| Machine Screws | Stainless Steel | Black Oxide | Very High | Metal to Metal Connections |

| Self-Tapping Screws | Copper | Clear Zinc | Medium | Sheet Metal Work |

| Drywall Screws | Carbon Steel | Phosphate | Medium | Drywall Installation |

| Lag Screws | Galvanized Steel | Hot Dip Galvanized | High | Heavy Load Applications |

Tips for Proper Installation Techniques to Avoid Common Mistakes

When tackling furniture assembly, the importance of proper installation techniques cannot be overstated. One of the most common mistakes made is using improper screw sizes, which can jeopardize the structural integrity of the furniture. According to the Furniture Industry Research Association, approximately 23% of furniture failures are attributed to incorrect fastener choices during assembly. Therefore, it’s crucial to select screws that not only match the material but also provide adequate grip without splitting the wood. A general rule of thumb is to choose screws that penetrate at least one and a half times the thickness of the object being joined for optimal strength.

In addition to selecting the right screws, employing the correct installation techniques can make a significant difference. For instance, pre-drilling holes is recommended to ensure accuracy and prevent wood from splitting, especially in dense hardwoods. A study by the National Wood Flooring Association highlighted that properly pre-drilled screws reduce the risk of material failure by up to 15%. Moreover, using a consistent torque when driving screws can prevent stripping, which is a common issue in furniture assembly. Properly aligning screws and ensuring that they are flush with the surface will not only enhance the aesthetic appeal but also improve the overall durability of the finished piece. Adopting these techniques can help avoid common pitfalls and lead to more successful furniture projects.

Related Posts

-

Revolutionizing Home Assembly: The Essential Role of Furniture Fasteners Explained

-

7 Compelling Reasons Why Square Neck Bolts Are Essential for Your Projects

-

Exploring Button Head Bolts: The Unsung Heroes of Modern Engineering Applications

-

Understanding the Versatility of Carriage Bolts: Essential Guide for DIY Enthusiasts

-

5 Essential Tips for Choosing the Right Truss Head Carriage Bolt for Your Project

-

Unlocking Industry Trends: Mushroom Head Screws at the 138th Canton Fair 2025