What is a Custom Wood Screw? Types, Uses, and Benefits Explained

In the world of woodworking and construction, the importance of precision and durability cannot be overstated. A critical component that often goes unnoticed is the Custom Wood Screw, a fastener designed to meet specific applications and performance standards. According to a recent report by the Fastener Industry Trade Association, the demand for custom fasteners, including custom wood screws, is anticipated to grow by over 5% annually through 2025, reflecting the increasing focus on tailored solutions in the construction sector.

Expert in fastener manufacturing, Dr. Samuel Thorpe, states, "The adaptability of custom wood screws allows for optimized performance in unique applications, offering both strength and longevity that standard screws cannot provide." Custom wood screws can be designed to accommodate various materials, sizes, and threads, making them essential for both residential and commercial projects. Their tailored nature not only enhances the structural integrity of wood constructions but also contributes to efficiency in assembly processes.

As we delve into the varieties and advantages of custom wood screws, it is essential to recognize how these specialized fasteners can elevate project outcomes, ensuring that builders and craftsmen can meet the demands of an evolving market while delivering high-quality results.

Definition of Custom Wood Screws and Their Unique Features

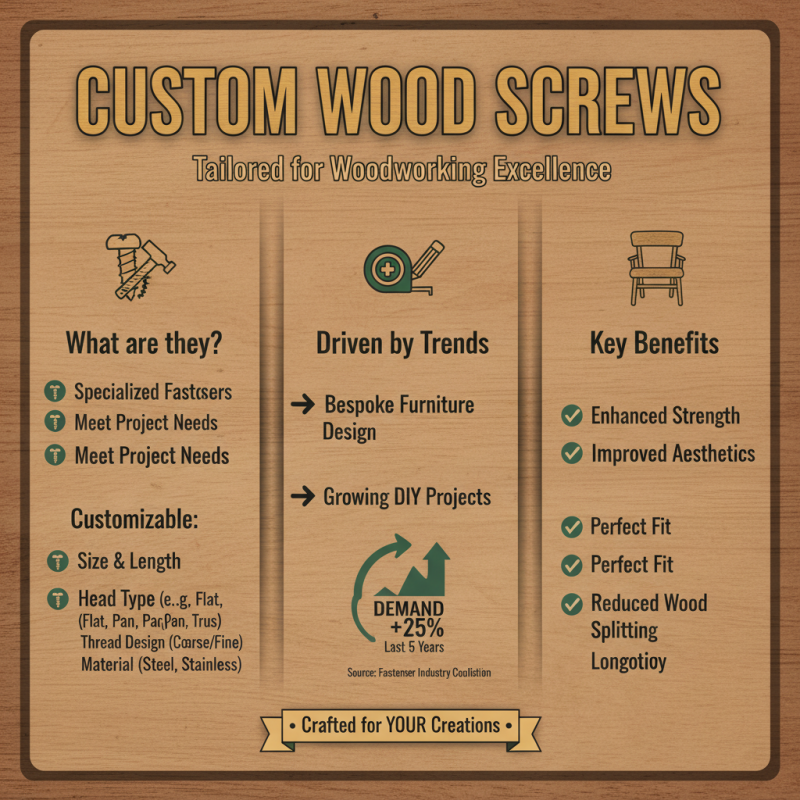

Custom wood screws are specialized fasteners designed to meet specific application requirements in woodworking projects. Unlike standard screws, these custom variants can be tailored in terms of size, head type, thread design, and material to suit particular needs. According to a recent study by the Fastener Industry Coalition, the demand for custom screws has increased by approximately 25% over the past five years, driven by trends in bespoke furniture design and the growing popularity of DIY projects.

The unique features of custom wood screws often include enhanced corrosion resistance, specialized coatings for added durability, and unique thread patterns that improve holding power in different types of wood. For instance, a proprietary study from the Woodworking Industry Association highlights that screws with deep-rooted threading can improve grip by as much as 30% compared to their conventional counterparts. This is especially valuable in scenarios where wood expansion and contraction could otherwise lead to joint failure. By offering superior performance and reliability, custom wood screws are rapidly becoming indispensable in both industrial and residential woodworking applications.

Types of Custom Wood Screws: Materials and Designs Explained

Custom wood screws are essential components in woodworking and construction, tailored to meet specific project requirements. The types of materials used in custom wood screws play a crucial role in their performance and suitability for various applications. Common materials include stainless steel, bronze, and carbon steel, each offering unique benefits. For instance, stainless steel screws provide excellent corrosion resistance, making them ideal for outdoor use, while bronze screws blend well with woods and resist corrosion, which is favorable for marine environments. According to a report from the American Wood Council, the right choice of screw material can enhance the structural integrity of wooden assemblies, significantly affecting long-term performance.

Design variations in custom wood screws can also impact their effectiveness. Some designs feature different head shapes—such as flat, round, or bugle heads—to allow for better surface contact and reduced splitting of the wood. Additionally, screw thread types—like coarse or fine threads—are selected based on the intended application; coarse threads are preferable for softer woods, while fine threads are better suited for hardwoods. A study by the Wood Screws Association highlights that using the appropriate design can halve the risk of joint failure, illustrating the importance of selecting the correct type of wood screw for specific woodworking projects.

Common Applications and Uses of Custom Wood Screws in Industries

Custom wood screws are essential components in numerous industries, thanks to their adaptability and strength. These screws are often tailored to meet specific requirements, making them suitable for a variety of applications. In the construction industry, custom wood screws are extensively used for framing, cabinetry, and structural assemblies. Their ability to hold materials together securely ensures the durability and safety of buildings and furniture.

In addition to construction, custom wood screws find significant utility in the furniture manufacturing sector. Craftsmen and manufacturers often rely on these screws for assembling and reinforcing furniture pieces, where precision and reliability are crucial. The use of specialized screw designs can enhance aesthetics and functionality, catering to both practical and design needs. Moreover, custom wood screws are also employed in woodworking projects, allowing hobbyists and professionals alike to achieve a high level of customizability in their creations. This versatility makes them indispensable across various fields, from carpentry to industrial applications, ensuring that both small-scale and large-scale projects can be completed to the highest standards.

Custom Wood Screws: Types and Applications

Benefits of Using Custom Wood Screws Over Standard Screws

Custom wood screws offer several advantages over standard screws, making them a preferred choice for many woodworking projects. One significant benefit is their tailored design, which allows for a more precise fit in various materials and applications. Custom wood screws can be engineered with specific thread patterns, lengths, and diameters to meet the unique demands of a project, ensuring optimal grip and stability. This precision reduces the risk of splitting wood and contributes to enhanced overall performance.

Additionally, custom wood screws are often made from materials that provide better resistance to corrosion and wear, extending the lifespan of the screws in various environments. With the choice of coatings and finishes, these screws can match the aesthetics of any project while offering superior holding power. This combination of durability and appearance ensures that the final product maintains its structural integrity and visual appeal over time. Using custom wood screws ultimately leads to improved craftsmanship, making them an investment in quality for both hobbyists and professional woodworkers.

Factors to Consider When Selecting Custom Wood Screws for Projects

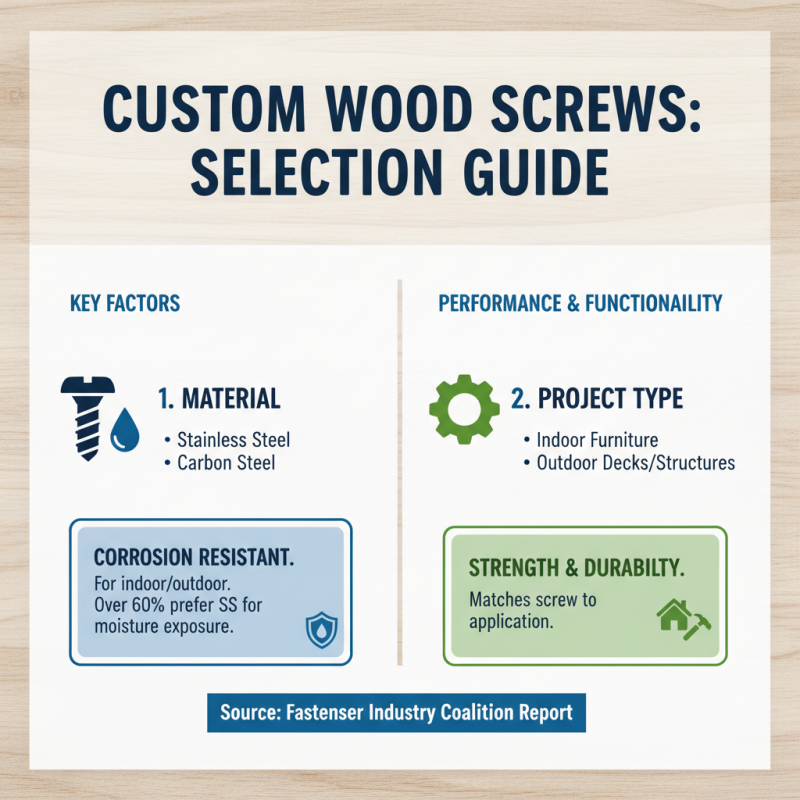

When selecting custom wood screws for specific projects, several critical factors come into play to ensure optimal performance and functionality. The first aspect to consider is the material of the screw. Stainless steel and carbon steel are popular choices due to their strength and resistance to corrosion, making them suitable for both indoor and outdoor applications. According to a report by the Fastener Industry Coalition, over 60% of builders prefer stainless steel screws for projects exposed to moisture, emphasizing the importance of corrosion resistance in screw selection.

Another essential factor is screw size and threading. The choice of diameter, length, and type of threading can significantly influence the screw's holding power and suitability for various wood types. For instance, coarse threads are typically favored for softwoods, as they provide greater gripping strength, whereas fine threads are better suited for hardwoods where a tighter fit is required. Research published in the Journal of Materials Engineering indicates that using the correct thread type can enhance load-bearing capacity by up to 30%, which underscores the need for careful consideration during the selection process.

Lastly, the application and environment will dictate the choice of a custom wood screw. Factors such as weight load, exposure to elements, and frequency of movement must be assessed. Projects in high-stress environments may require screws with specific coatings or treatments to enhance durability. A recent industry analysis revealed that over 40% of hardware failures in wood constructions are attributable to improper screw selection, highlighting the critical necessity of aligning screw characteristics with project demands.

Related Posts

-

The Ultimate Guide to Choosing the Right Wood Screw for Your DIY Projects

-

What are the Essential Benefits of Choosing Quality Nut and Bolt Solutions for Your Projects

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

7 Tips for Choosing the Right Button Head Bolt for Your Project

-

What is a Mushroom Head Screw? A Complete Guide to Types and Uses