How to Choose the Right Stainless Bolts for Your Project Needs

When embarking on a project that requires durable fastening solutions, the significance of choosing the right stainless bolts cannot be overstated. As industry expert John Smith, a renowned engineer with over twenty years of experience in the fastener sector, aptly stated, "Selecting the appropriate stainless bolts is crucial not only for the integrity of the assembly but also for ensuring long-term performance in various environmental conditions." This insight serves as a starting point for understanding the complexities involved in the selection process.

Stainless bolts offer an array of advantages, including corrosion resistance and strength. However, with multiple grades and types available in the market, it can be challenging to navigate the nuances of what best suits your specific needs. Users must consider factors such as material composition, tensile strength, and the environmental conditions the bolts will face.

In this guide, we'll explore essential criteria for selecting stainless bolts, providing you with the knowledge to make informed decisions that will enhance the quality and longevity of your projects. By the end, you'll be equipped to choose the right type of stainless bolts that not only align with your project goals but also withstand the test of time.

Understanding Different Types of Stainless Steel Bolts Available

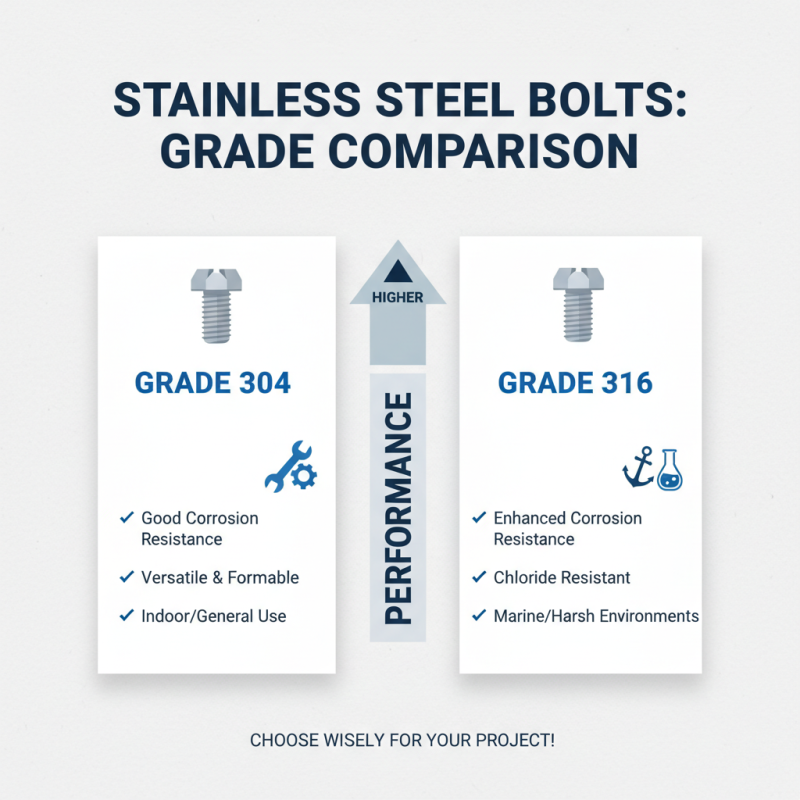

When selecting the right stainless steel bolts for your project, it's essential to understand the various types available and their specific applications. Stainless steel bolts can be broadly categorized into several grades, with 304 and 316 being the most common. Grade 304 is often suitable for general use, offering good corrosion resistance in a variety of environments. However, for projects exposed to harsher conditions, such as marine applications or chemical processing, Grade 316 with its enhanced corrosion resistance becomes the preferred choice.

Additionally, the design of stainless steel bolts can vary significantly, impacting their performance based on the nature of the task. For instance, hex bolts are ideal for heavy-duty applications, while carriage bolts provide a smooth finish and are excellent for fastening wood. The growing industrial fasteners market highlights an increasing demand for innovative fastening solutions as construction methods and materials evolve. Understanding these differences allows you to select the most appropriate stainless steel bolts, ensuring durability and reliability in your projects.

Evaluating Material Grades for Specific Project Requirements

When selecting stainless bolts for your project, understanding material grades is crucial. Stainless steel bolts are available in various grades, each offering different properties and benefits. Common grades include 304 and 316, with 304 being widely used for its good corrosion resistance and formability, making it suitable for many indoor applications. However, for projects exposed to harsher environments, such as marine applications or chemical processing, grade 316 is preferable due to its enhanced corrosion resistance, particularly against chlorides.

Additionally, it's essential to consider the specific requirements of your project. Factors such as load-bearing capacity, fatigue strength, and environmental conditions play a significant role in material selection. For high-stress applications, opting for high-strength stainless steel bolts or those with specific coatings can ensure longevity and performance. By carefully evaluating these material grades against your project needs, you can make an informed decision that ensures the safety and durability of your assembly.

Identifying Corrosion Resistance Needs for Your Environment

When selecting stainless bolts for a project, understanding the corrosion resistance needs of your specific environment is crucial. According to a report by the International Stainless Steel Forum (ISSF), approximately 80% of stainless steel failures in construction are attributed to inadequate corrosion resistance. This demonstrates the importance of selecting the appropriate grade of stainless steel based on the exposure conditions.

For environments that are exposed to harsh conditions, such as marine or chemical settings, Type 316 stainless steel is often recommended due to its superior resistance to chlorides and other corrosive agents. A study published by the Corrosion Engineering Society indicated that Type 316 can withstand a saline environment up to ten times better than Type 304. Conversely, for less demanding applications, Type 304 bolts may suffice, offering a good balance of corrosion resistance and cost.

Moreover, assessing environmental factors, such as humidity levels and temperature fluctuations, should guide your choice. In areas with high humidity or frequent rain, the likelihood of corrosion increases, thus necessitating the selection of higher-grade stainless steel. The American Galvanizers Association (AGA) suggests considering not only the material but also the protective coatings available to enhance longevity and performance of stainless steel bolts under specific conditions.

Choosing the Right Bolt Size and Thread Type for Fit and Strength

When selecting stainless bolts for your project, the right bolt size and thread type are crucial for ensuring optimal fit and strength. First, consider the diameter and length of the bolt. The diameter affects the load-bearing capacity, while the length must accommodate the thickness of the materials being fastened. It's essential to measure accurately and account for any additional components such as washers or nuts that may introduce extra thickness.

Equally important is the choice of thread type, which influences how well the bolt will grip the materials it connects. Common thread types include coarse, fine, and variable threads. Coarse threads are ideal for quick assembly and disassembly, while fine threads provide better tensioning capabilities, making them suitable for applications involving vibration or dynamic loads. Understanding the particular demands of your project will guide you in selecting the appropriate bolt size and thread type, ensuring both functionality and durability.

How to Choose the Right Stainless Bolts for Your Project Needs

| Bolt Size (Diameter) | Length (mm) | Thread Type | Material Grade | Tensile Strength (MPa) |

|---|---|---|---|---|

| M6 | 40 | Metric Fine | A2-70 | 700 |

| M8 | 60 | Metric Coarse | A4-80 | 800 |

| M10 | 75 | Metric Fine | A2-80 | 800 |

| M12 | 100 | Metric Coarse | A4-70 | 700 |

Considering Additional Features: Coatings, Finishes, and Certifications

When selecting stainless bolts for your project, one crucial aspect to consider is the additional features such as coatings, finishes, and certifications that can significantly impact performance and longevity. Coatings, like zinc plating or powder coating, offer enhanced corrosion resistance, making them ideal for outdoor or harsh environments. These protective layers can help prevent rust and degradation over time, ensuring that your fasteners remain reliable under varying conditions.

Finishes also play a vital role in the aesthetics and functionality of stainless bolts. A polished or brushed finish can improve the visual appeal, while also contributing to reduced friction when bolting components together. Furthermore, certifications such as ASTM and ISO standards ensure that the bolts meet specific quality and safety requirements. Choosing bolts that are certified can provide peace of mind, knowing they have been tested for structural integrity and performance, ultimately leading to better outcomes for your project.

Comparison of Stainless Bolt Features

Related Posts

-

Top 10 Stainless Bolt Types for Maximum Durability and Performance in 2023

-

7 Best Tips for Choosing the Right Stainless Bolt for Your Project

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Understanding the Importance of Carriage Bolt Selection in Construction Projects

-

How to Choose the Right Truss Head Carriage Bolt for Your Project

-

Ultimate Guide to Choosing the Right Hot Sale Carriage Bolt for Your Projects