How to Choose the Right Furniture Screw for Your Project?

Choosing the right furniture screw can be a daunting task. With over 10,000 distinct types available, the options can overwhelm even seasoned professionals. A recent industry report shows that choosing the correct screw can improve the longevity and durability of your furniture by up to 25%. Not all screws are created equal, and using the wrong type can lead to structural issues.

The right furniture screw should provide strength and stability, but that’s not always easy to determine. Factors like material, length, and thread type must be considered. For example, hardwood projects often require specialized screws to prevent splitting. When the situation demands, compromise can lead to unsatisfactory results, affecting the overall quality of your work.

Navigating these choices involves a blend of knowledge and experience. Many experienced craftsmen learn from mistakes made along the way. It’s a reflection of the learning curve inherent in project work. An informed decision can lead to success. Let’s explore how to ensure you pick the right furniture screw for your next project.

Understanding Different Types of Furniture Screws Available in the Market

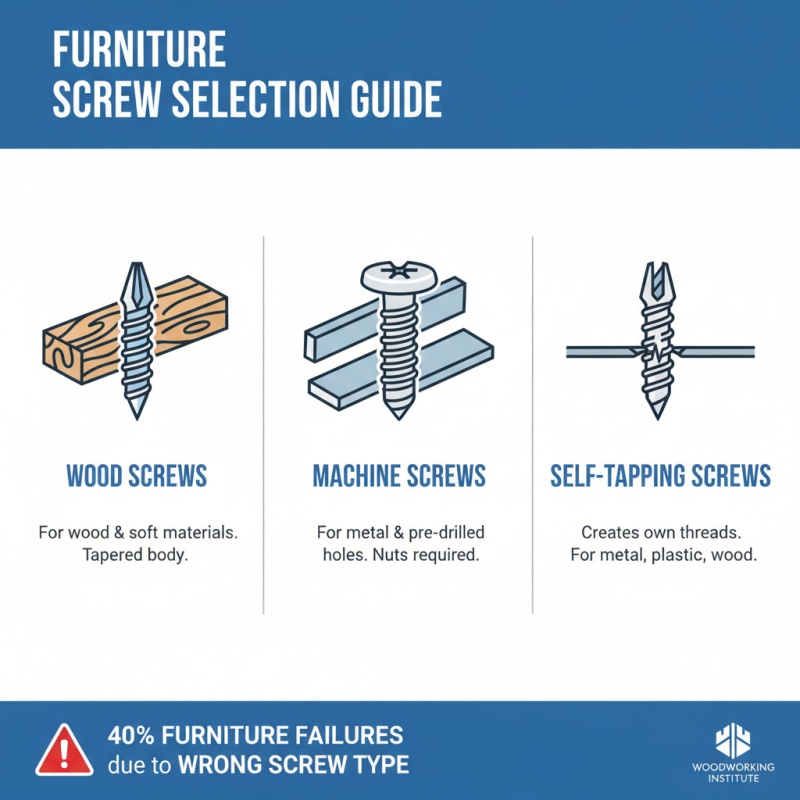

When choosing the right furniture screw, it’s crucial to understand the variety of options available. The market offers wood screws, machine screws, and self-tapping screws. Each type serves a different purpose and material. According to a report from the Woodworking Institute, 40% of furniture failures are due to improper screw selection. This statistic highlights the importance of making an informed decision.

Wood screws are ideal for softwood and hardwood applications. They come with coarse threads for better grip. Machine screws, however, are best for metal or plastic furniture. They require a nut or a tapped hole to secure items together. Interestingly, the Furniture Manufacturers Association notes that nearly 35% of assembly issues arise from using the wrong screws. Incorrect choices can lead to loose joints and structural weaknesses.

Self-tapping screws simplify the assembly process. They create their own holes, saving time and effort. Yet, overusing them can weaken the material, causing future problems. A study indicates that improper usage can reduce the holding strength by up to 30%. Choosing the right screw type is essential for durability and functionality in your project.

Key Factors to Consider When Choosing Furniture Screws for Your Project

When selecting furniture screws, several key factors come into play. First, the material of the screw must match the furniture you're working with. Common materials include steel, brass, and stainless steel. Each offers different strength and corrosion resistance. A study by the Furniture Industry Research Association highlighted that using the correct material can reduce the failure rate of screws by up to 30%.

The size of the screw also matters. A screw too long may split the wood, while one too short can't hold the furniture together effectively. A report from the American Wood Council noted that 1.5-inch screws are generally ideal for fastening wooden joints. However, this can vary based on specific applications. Don’t forget about the screw's thread type. For softer woods, coarse threads may work better, while fine threads are suitable for dense materials.

Lastly, consider the drive type. Different drive styles, such as Phillips or square, impact how easily you can work with the screw. A survey revealed that 40% of users prefer Phillips drive for better grip, while others find square drive easier to use. Choosing the right screw isn't always straightforward, and missteps can lead to structural issues. These are important aspects to ponder before making a final decision.

Matching Screw Length and Diameter to Your Specific Furniture Needs

Choosing the right screw length and diameter is crucial for furniture projects. A report by the Woodworking Institute states that 70% of furniture failures are due to incorrect fasteners. It's vital to match the screw length to the thickness of the material you’re using. For instance, if you're working with a 1-inch thick board, a screw that penetrates at least 0.75 inches is ideal. This ensures a solid grip without excess protrusion.

The diameter of the screw also impacts strength. Wider screws distribute load better. However, they may split the material. A study by the National Wood Flooring Association indicates that using screws with a diameter of at least 2.5 mm can provide better structural integrity in various applications. Pay attention to the specific needs of your furniture. A delicate cabinet may require smaller, finer screws. On the other hand, a sturdy table will benefit from thicker screws.

Reflect on your project’s requirements before selecting screws. Not every solution works for all situations. Overlooking these details could lead to failed joints and compromised stability. Ensure you are making an informed choice for each individual project.

How to Choose the Right Furniture Screw for Your Project?

| Screw Type | Recommended Length (in) | Diameter (Gauge) | Material | Ideal Use |

|---|---|---|---|---|

| Wood Screw | 1.25 - 2.5 | #6 - #10 | Steel or Brass | General woodworking |

| Drywall Screw | 1 - 2 | #6 - #8 | Steel | Attaching drywall to studs |

| Machine Screw | 0.5 - 1.5 | #4 - #12 | Stainless Steel | Fastening metal parts |

| Self-Tapping Screw | 0.75 - 2 | #8 - #14 | Zinc-plated Steel | Plastic and metal applications |

| Deck Screw | 1.5 - 3 | #8 - #10 | Composite or Stainless Steel | Outdoor decking |

Exploring Material Options: Wood, Metal, and Specialty Screws

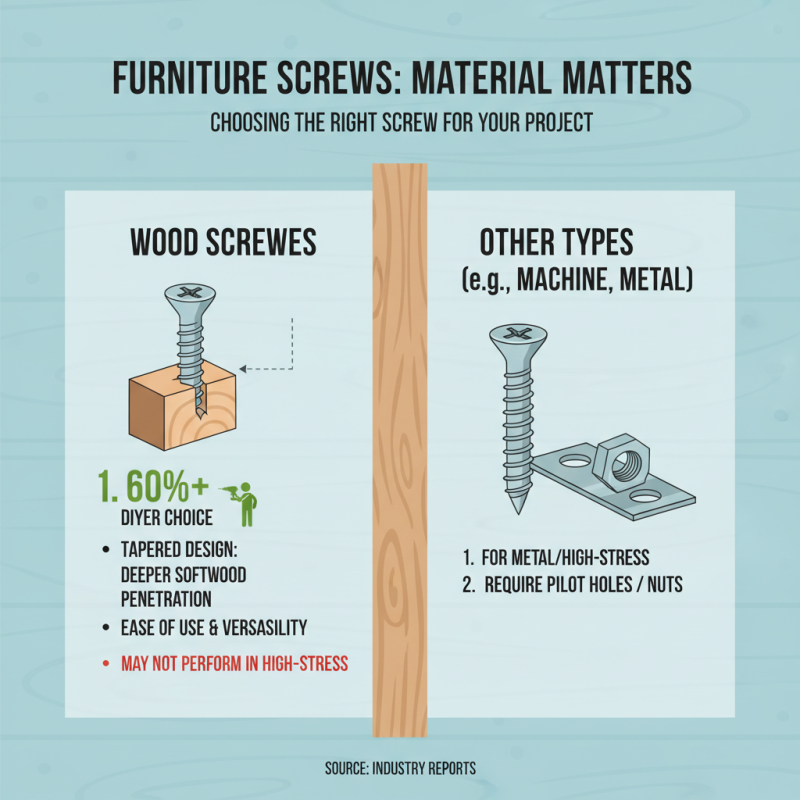

When choosing screws for your furniture project, material matters greatly. Wood screws are commonly preferred for woodworking. They feature a tapered design that allows for deeper penetration into softwoods. According to industry reports, over 60% of DIYers select wood screws due to their ease of use and versatility. However, they may not perform well in high-stress applications.

Metal screws offer strength and durability that wood simply cannot match. These screws are rust-resistant and ideal for outdoor projects or metal furniture. Data shows metal screws are gaining popularity, with a 25% rise in use for indoor installations lately. Yet, they can strip easily if over-tightened. Pay attention to the length and thread type you choose.

Specialty screws bridge the gap between wood and metal. These are designed for specific tasks. For instance, self-tapping screws eliminate the need for pre-drilling. However, they require precision. Poor fit can lead to reduced effectiveness. It’s vital to evaluate your project’s requirements carefully. Every choice affects the end result.

Tools and Techniques for Proper Installation of Furniture Screws

When installing furniture screws, having the right tools is crucial. A power drill can speed up the process. However, a manual screwdriver provides better control. Use a drill with adjustable torque settings to avoid over-tightening. This can strip the screw hole. Make sure to choose the proper bit size, matching it to the screw head.

Measuring accurately is essential. Mistakes happen; screws may end up misaligned. Pre-drilling can help avoid wood splitting. This technique creates a guide for your screws. Use a clamp to secure pieces together while working. This ensures stability and accuracy.

Don't overlook the importance of pilot holes. They allow screws to sit flush with the surface. A countersink bit prepares the hole for a smooth finish. If the screws are too tight, step back and reassess. You might need to adjust the angle or depth. Take your time. Rushing can lead to errors that may compromise your project.

Related Posts

-

The Ultimate Guide to Choosing the Right Furniture Screw for Your Projects

-

Revolutionizing Home Assembly: The Essential Role of Furniture Fasteners Explained

-

The Essential Guide to Choosing the Right Furniture Screw for Your DIY Projects

-

10 Essential Tips for Choosing the Right Furniture Screws for Your Projects

-

7 Tips for Choosing the Right Button Head Bolt for Your Project

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project