How to Choose High Tensile Carriage Bolt for Your Project?

Choosing the right fasteners is vital for any project. One popular option is the High Tensile Carriage Bolt. These bolts are designed to withstand significant pressure, making them suitable for heavy-duty applications. They feature a smooth, domed head, which prevents snagging.

When selecting a High Tensile Carriage Bolt, consider materials. Bolts come in various grades, affecting strength and corrosion resistance. Steel, for example, is strong and durable. However, it may rust without proper treatment.

Many overlook the importance of size. A bolt too long may weaken the structure, while a short one could fail under pressure. Think about the specific needs of your project. Reflection on these details will help ensure lasting stability and performance.

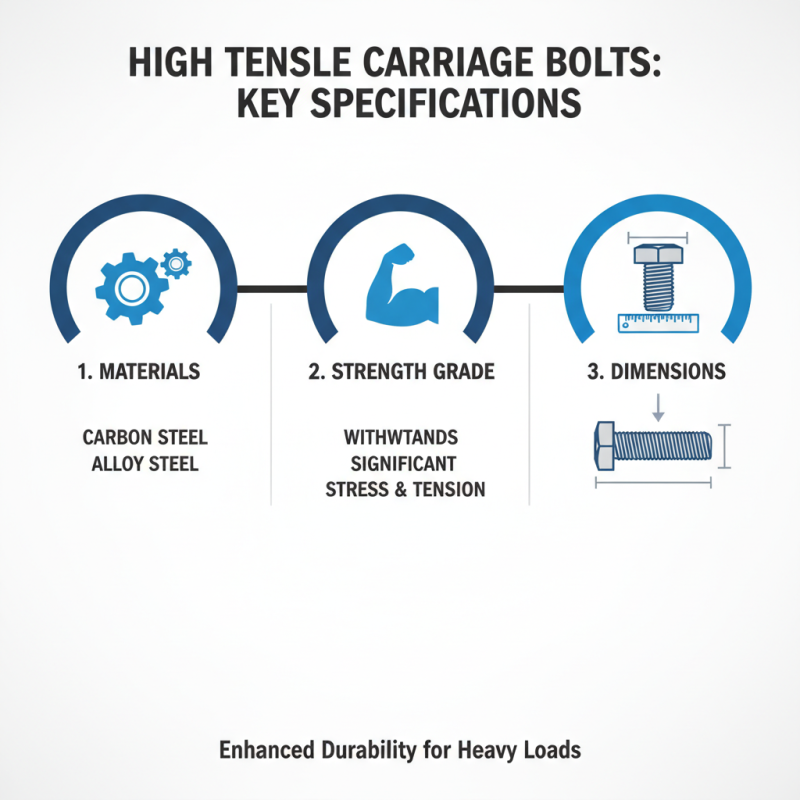

Understanding High Tensile Carriage Bolt Specifications and Standards

When selecting high tensile carriage bolts, understanding specifications is crucial. High tensile bolts are designed to withstand significant stress and tension. Their specifications generally include materials, strength grades, and dimensions. Common materials for these bolts are carbon steel and alloy steel. These materials enhance durability and performance in heavy-load applications.

Strength grades play a vital role too. The most common grades range from 8.8 to 12.9. Each grade indicates the tensile strength and yield strength of the bolt. For example, a grade 10.9 bolt can handle more stress than a grade 8.8 one. Not every project needs the highest grade, though. Over-specifying could lead to increased costs without substantial benefits.

Dimensions are another key factor. Check the length, diameter, and head type to ensure a proper fit. Pay attention to the surface finish as well. Zinc plating or hot-dip galvanizing improves corrosion resistance. However, these finishes can add extra thickness. This might complicate compatibility with precise fitting requirements. Therefore, consider these specifications carefully to avoid costly mistakes.

Material Selection for High Tensile Carriage Bolts: Strength and Durability

When selecting high tensile carriage bolts, the material is crucial. These bolts bear significant loads and must withstand stress. Typically, steel is the go-to material due to its strength and durability. However, not all steel is created equal. Carbon steel bolts often provide excellent tensile strength but can corrode over time if not treated. It's essential to think about the environment in which they will be used.

Stainless steel is another option. It resists rust and corrosion better than carbon steel. This makes it a smart choice for outdoor applications or damp areas. However, stainless steel bolts can be more expensive. When weighing options, consider the project's specific needs. Will the bolts be exposed to moisture? What are the load requirements? These factors should inform your decision.

Additionally, always keep in mind that even high tensile materials can fail under extreme conditions. It’s wise to evaluate the potential for fatigue or other forms of failure. Your project deserves careful consideration of all aspects. Balancing cost with performance is key. A failure might lead to expensive repairs or safety hazards. Take time to assess the best material for your carriage bolts.

Determining the Correct Size and Length for Your Carriage Bolt Needs

Choosing the right size and length for high tensile carriage bolts is crucial for any project. The diameter of the bolt significantly impacts the load-bearing capacity. According to industry data, bolts with diameters ranging from 1/4 inch to 1 inch can handle loads from 1,200 to 10,000 pounds, depending on their material and treatment. It’s important to understand the weight requirements of your application.

Length is another critical factor. A bolt that is too short might not properly secure materials, while one that is excessively long could cause interference or alignment issues. Industry standards suggest that a minimum of one inch of thread engagement is ideal for most projects. This can ensure you get a strong hold without compromising safety.

Selecting a high tensile carriage bolt is not straightforward. Many factors can affect performance. For instance, environmental conditions can corrode the metal, weakening its strength. Regular inspections are often overlooked but essential for long-term use. Failure to address these issues can lead to catastrophic outcomes in construction or machinery applications.

Carriage Bolt Size and Length Comparison

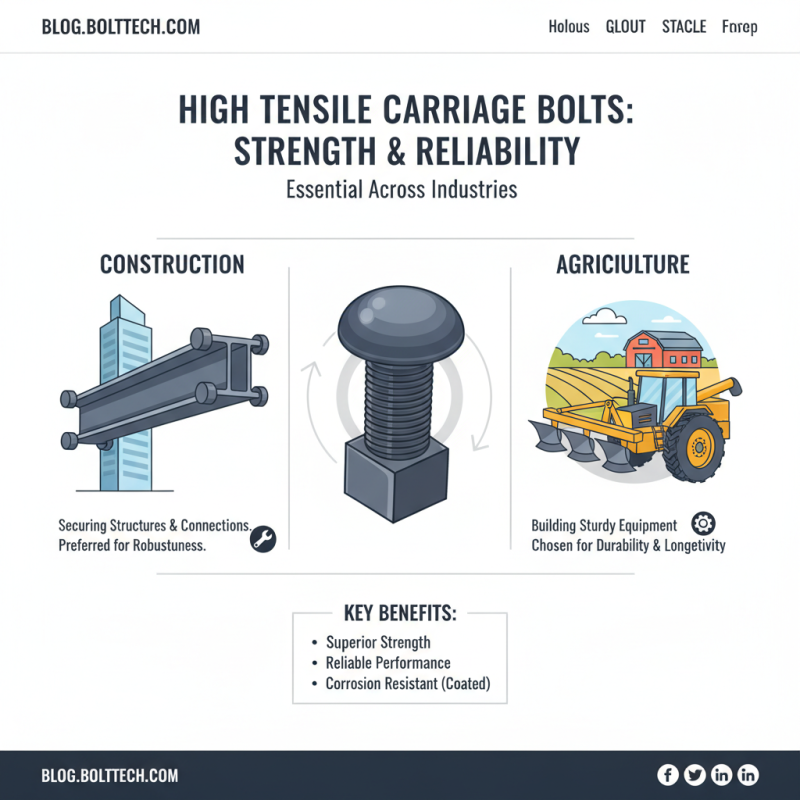

Applications of High Tensile Carriage Bolts in Various Industries

High tensile carriage bolts are vital in various industries. They are known for their strength and reliability. Many construction projects rely on these bolts for securing structures and connections. In agriculture, they help build sturdy equipment. Farmers prefer high tensile bolts for long-lasting solutions.

In the automotive sector, high tensile carriage bolts play a key role in assembly and maintenance. They ensure that components stay firmly in place. However, it’s crucial to choose the right size and grade. Incorrect specifications can lead to failures. Many people overlook these details, resulting in costly repairs later on.

The manufacturing industry also benefits from high tensile carriage bolts. They are essential in machinery assembly. Proper selection ensures machines operate safely and efficiently. Some engineers may skip thorough testing during the installation process. This might lead to unexpected breakdowns. Continuous assessment is vital for optimal performance.

Installation and Maintenance Best Practices for High Tensile Carriage Bolts

Installing high tensile carriage bolts requires attention to detail. Start by ensuring you have the right tools. A wrench and torque gauge work well. Before installation, check the bolt threads for any damage. Damaged threads can lead to improper fitting. Always clean the surfaces where you will place the bolts. Debris can reduce the effectiveness of the fastening.

When tightening the bolts, be careful not to overtighten them. This can cause the bolts to break or the materials to warp. Use a torque wrench to apply even pressure. Sometimes, bolts might loosen over time due to vibration or thermal expansion, so regular checks are necessary. Inspect them periodically, especially in high-stress applications.

Maintenance is crucial for longevity. Keep an eye out for rust or corrosion. These issues can compromise the integrity of high tensile bolts. If you notice any wear, replace the bolts promptly. A proactive approach can save time and enhance safety. Remember, even high-quality bolts need care. Reflect on your practices and adjust as necessary for your project's success.

Related Posts

-

How to Choose the Perfect Hot Sale Carriage Bolt for Your Project

-

How to Choose the Right High Tensile Carriage Bolt for Your Project Needs

-

Understanding the Advantages of High Tensile Carriage Bolts for Structural Integrity in Modern Constructions

-

Top 10 High Tensile Carriage Bolt Uses Benefits and Buying Guide

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Ultimate Guide to Choosing the Right Hot Sale Carriage Bolt for Your Projects