How to Choose High Quality Carriage Bolts for Your Projects in 2025

In the ever-evolving landscape of construction and DIY projects, the selection of fasteners plays a critical role in the overall integrity and success of any endeavor. As we approach 2025, the demand for reliable and durable components has surged, particularly for "High Quality Carriage Bolts". According to renowned industry expert John Anderson, “The key to a successful project lies in the details, and choosing high quality fasteners is non-negotiable.” His insights underscore the significance of investing in superior carriage bolts that can withstand the test of time and tension.

When selecting high-quality carriage bolts, several factors come into play, such as material, design, and manufacturing standards. With advancements in technology, the options available today are more varied than ever before, allowing builders and hobbyists alike to leverage improved features that enhance safety and performance. As the industry shifts toward sustainable practices, understanding the qualities that define a high-quality carriage bolt becomes essential for anyone looking to complete their projects with both efficacy and environmental consideration.

In this guide, we will explore the key features that distinguish high-quality carriage bolts, as well as practical tips for choosing the right ones for your specific applications. Whether you're engaging in construction, woodworking, or home improvement, making informed decisions about your fasteners will ensure that your projects not only meet expectations but exceed them in durability and resilience.

Understanding the Basics of Carriage Bolts and Their Uses

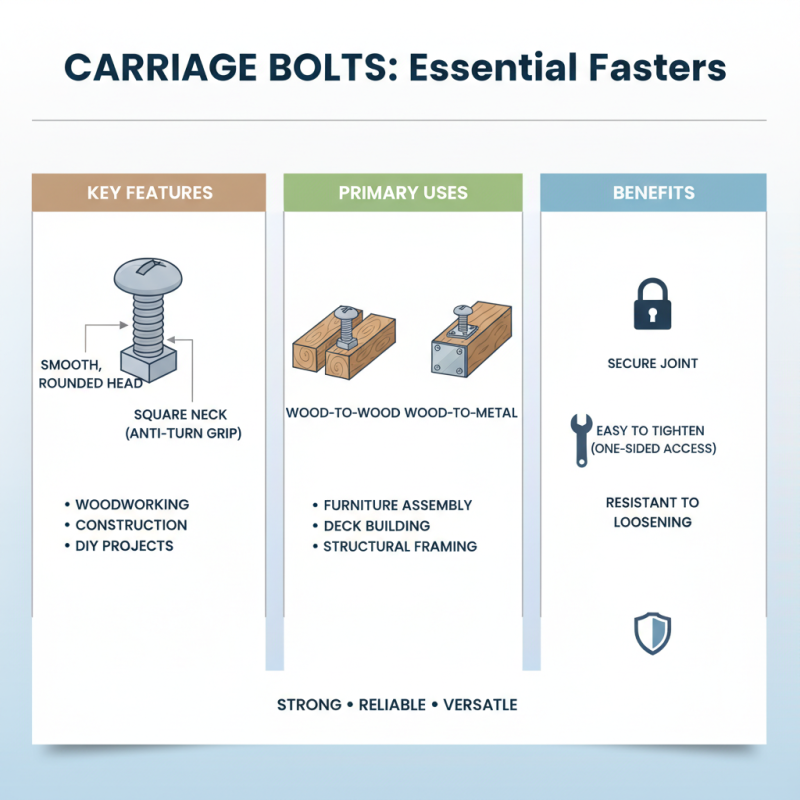

Carriage bolts are essential fasteners often used in woodworking, construction, and various DIY projects. Characterized by their smooth, rounded heads and square necks, carriage bolts provide a secure grip that resists turning when tightened. The design makes them ideal for joining wood to wood or wood to metal, making them a staple in building furniture, decks, and other structures where a strong bond is necessary.

When selecting carriage bolts for your projects, it’s crucial to understand their various applications. For instance, longer bolts are typically preferred for thicker materials, while shorter bolts work well for lighter assemblies. Additionally, the materials from which the bolts are made can significantly impact their performance—options range from carbon steel for general use to stainless steel for environments exposed to moisture or corrosive elements.

**Tips:** Always consider using washers with carriage bolts to distribute the load and prevent damage to the materials being fastened. Moreover, ensure that the diameter of the bolt matches the needs of your project to avoid structural weaknesses. Lastly, if you're working with treated wood, opt for bolts that are resistant to corrosion to ensure durability over time.

Identifying Key Features of High-Quality Carriage Bolts

When selecting high-quality carriage bolts for your projects in 2025, it is essential to focus on key features that ensure durability and functionality. One of the primary indicators of a quality carriage bolt is the material from which it is made. Opt for bolts crafted from high-strength steel or stainless steel, as these materials provide superior resistance to corrosion and wear. Additionally, verify the hardness rating of the bolts; a higher rating indicates greater durability and strength under load.

Another important feature to consider is the finish of the carriage bolt. A galvanized or coated finish can enhance its longevity by providing additional protection against the elements. Pay attention to the thread design as well; well-cut threads offer better grip and prevent stripping, ensuring a secure fastening.

Tips: Always check for certifications or standards compliance on the packaging to guarantee the quality of the bolts. When purchasing in bulk, consider the seller's return policy, as this can give you reassurance about the product's quality. Lastly, don’t forget to consider the size and length of the carriage bolts; proper sizing is crucial for the effectiveness of your project.

Evaluating Materials and Coatings for Durability

When selecting carriage bolts for your projects in 2025, understanding the materials and coatings available is crucial for ensuring longevity and performance. According to the American Society of Mechanical Engineers (ASME), the strength and durability of fasteners are heavily influenced by their material composition. Common materials for carriage bolts include carbon steel, stainless steel, and alloy steel, each offering varying degrees of tensile strength and corrosion resistance. For instance, stainless steel, which provides excellent resistance to rust and corrosion, is ideal for outdoor applications where exposure to moisture is a concern. Reports from industry analysts suggest that the demand for stainless steel fasteners is projected to grow by 7% annually due to their superior performance characteristics in harsh environments.

Coatings also play a significant role in the longevity of carriage bolts. A study published in the Journal of Coatings Technology highlighted that galvanized coatings can increase the lifespan of bolts by up to 30 years when used in corrosive settings. Meanwhile, other advanced coatings, such as zinc-nickel, are gaining traction in the market due to their enhanced durability and resistance to flaking and peeling. With evolving technology in corrosion resistance, choosing the right coating can make a substantial difference in the performance of your projects. Prioritizing materials and coatings that align with the specific demands of your application will ensure that your carriage bolts not only endure but also support the structural integrity of your projects over time.

Considering Size and Length Requirements for Your Projects

When selecting carriage bolts for your projects, one of the most critical factors to consider is the size and length requirements. According to the Fastener Quality Act, the strength and performance of fasteners like carriage bolts are significantly influenced by their dimensions. The diameter of the bolt is particularly important; commonly, options range from 1/4 inch to 1 inch. A proper diameter ensures that the bolt can properly bear the load without risking strip out of the material it’s fastened into, which is imperative for structural integrity.

In terms of length, a recent report by the Industrial Fasteners Institute suggests that for most applications, the length of carriage bolts should exceed the thickness of the materials they are intended to join by at least one inch to ensure proper engagement of the nut and threaded portion. This is critical because inadequate length may compromise the bolt's ability to hold materials securely under stress. Additionally, it is crucial to account for the thickness of any washers or spacers that may be used in conjunction. Always considering these size and length parameters while choosing carriage bolts will contribute to the durability and reliability of your project outcomes.

How to Choose High Quality Carriage Bolts for Your Projects in 2025 - Considering Size and Length Requirements for Your Projects

| Bolt Size | Length (inches) | Material | Grade | Recommended Use |

|---|---|---|---|---|

| 1/4" | 1" | Steel | Grade 5 | Light-duty applications |

| 5/16" | 2" | Stainless Steel | Grade 316 | Outdoor projects |

| 3/8" | 3" | Carbon Steel | Grade 8 | Heavy-duty applications |

| 1/2" | 4" | Aluminum | Not rated | Lightweight structures |

| 5/8" | 6" | Brass | Not rated | Decorative applications |

Best Practices for Purchasing and Sourcing Carriage Bolts

When selecting high-quality carriage bolts for your projects in 2025, it's crucial to understand the specifications and materials that ensure longevity and reliability. Start by assessing the load requirements of your project. Carriage bolts are available in various grades, generally classified as low, medium, and high strength. For heavy-duty applications, opt for higher-grade bolts, which can withstand greater stress without deforming.

**Tips:** Pay attention to material types. Stainless steel and galvanized options offer excellent corrosion resistance, making them ideal for outdoor projects or environments prone to moisture. Furthermore, consider the finish; a smooth finish will provide a better aesthetic and prevent snagging during installation.

Another best practice is to source your carriage bolts from reputable suppliers. Established vendors often provide detailed specifications and quality assurance that less reliable sources may lack. Don’t hesitate to inquire about certifications or testing standards they follow to assess the product’s reliability.

**Tips:** Always buy in bulk when possible to reduce costs and ensure consistent quality across your project. Remember to check customer reviews or ratings of the suppliers; other users' experiences can provide insight into not just the product quality but also the seller's service reliability.

Carriage Bolt Usage by Material Type (2025)

Related Posts

-

Exploring the Benefits of Using High Tensile Carriage Bolts for Your Construction Projects

-

Understanding the Advantages of High Tensile Carriage Bolts for Structural Integrity in Modern Constructions

-

How to Choose the Right Carriage Bolt for Your Next Project

-

Exploring the Benefits and Applications of Mushroom Head Carriage Bolts in Modern Construction

-

7 Compelling Reasons Why Square Neck Bolts Are Essential for Your Projects

-

What is a Mushroom Head Screw? A Complete Guide to Types and Uses