Why Choose Stainless Torx Screws for Your Projects?

In the realm of construction and manufacturing, the choice of fasteners significantly impacts project success. Stainless Torx Screws have gained popularity due to their unique benefits. According to a recent report by the Fastener Quality Act, the demand for stainless fasteners is expected to rise by 12% in the next five years. This statistic highlights the critical role of materials like stainless steel in modern applications.

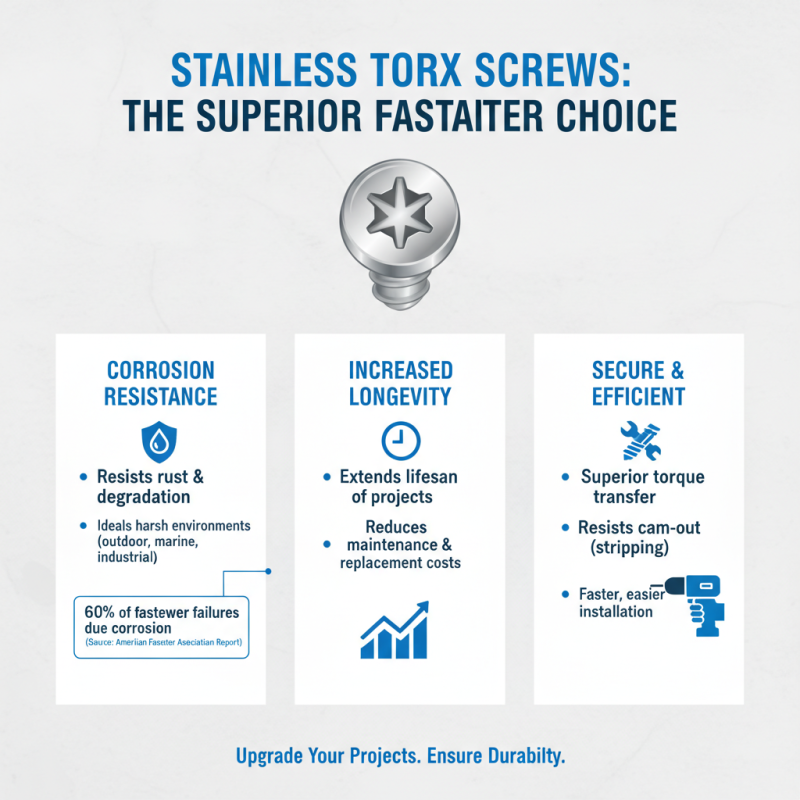

Stainless Torx Screws offer excellent corrosion resistance, making them ideal for outdoor projects. Unlike traditional screws, they are less prone to stripping, providing a reliable grip. However, some may overlook their higher cost. It's essential to weigh these expenses against the long-term durability benefits. Research indicates that using quality fasteners can prolong product life by up to 30%.

Efficiency in assembly is another advantage. The Torx design allows for greater torque transfer, reducing the risk of cam-out. While these screws may require specialized tools, the investment can lead to improved overall productivity. In a world where efficiency matters, opting for Stainless Torx Screws may be a wise choice, albeit with considerations about cost and tooling.

Understanding Stainless Torx Screws: A Comprehensive Overview

Stainless Torx screws are gaining popularity in various projects. Their distinctive shape offers several advantages. The star-shaped design allows for better torque. This leads to fewer chances of stripping. They also resist corrosion, making them ideal for outdoor use.

When selecting stainless Torx screws, consider their material. Stainless steel is durable and resists rust. However, not all stainless steel is created equal. Some grades perform better than others. Take time to understand the specific needs of your project. This small effort can pay off in the long run.

Tips: Always match the screw size to the job. Choosing the wrong size can weaken your assembly. Test a few screws to find the best fit. Also, use the right Torx driver. A poor fit can damage both the screw and the tool. Pay attention to these details to ensure success.

Key Benefits of Using Stainless Torx Screws in Various Applications

Stainless Torx screws are gaining popularity in many projects. Their unique design offers several key benefits in various applications. One major advantage is their resistance to corrosion. According to a report by the American Fastener Association, approximately 60% of fastener failures result from corrosion issues. Choosing stainless Torx screws mitigates this risk, increasing the longevity of installations in harsh environments.

Another significant benefit is the enhanced drive efficiency. Torx screws feature a star-shaped socket that provides greater grip for drivers. Studies show that users experience a 25% increase in torque transfer compared to traditional screws. This translates to easier installation and less wear on tools. However, some users overlook the need for proper fit. Using improper sizes can lead to stripped heads and improper torque application, undermining these benefits.

Lastly, stainless Torx screws contribute to aesthetics and clean finishes. Features like reduced cam-out reduce visible damage around the screw site. While they are more visually appealing, some projects may still require careful consideration for design consistency. Overall, the advantages offered by stainless Torx screws often outweigh their drawbacks when chosen carefully.

Comparative Analysis: Stainless Torx Screws vs. Other Fasteners

Stainless Torx screws have unique advantages compared to other fasteners. They provide superior grip with their star-shaped recess. This design reduces cam-out issues, ensuring a tighter fit. Many traditional screws can strip easily. This is particularly challenging in projects requiring precision.

When comparing stainless Torx screws to Phillips or flat-head screws, differences become clear. Phillips screws can slip during installation. On the other hand, flat-head screws may not offer the same torque. Torx screws are often more resistant to rust and corrosion. This makes them ideal for outdoor use or in harsh environments.

However, Torx screws aren’t perfect. They may require a specific tool to install. In some situations, this could be inconvenient. Project managers should evaluate whether the added benefits justify this requirement. Understanding these nuances is vital for effective project execution.

Comparative Analysis: Stainless Torx Screws vs. Other Fasteners

Installation Techniques for Optimal Performance of Stainless Torx Screws

Stainless Torx screws have gained popularity in various projects due to their durability and corrosion resistance. When installing these screws, using the right techniques is crucial for optimal performance. Proper torque application helps prevent stripping. Over-tightening can damage both the screw and the material. It’s essential to find a balance.

One effective tip is to ensure the screw fits snugly into the driver. A loose fit may lead to slipping. This can be frustrating, especially during critical installations. Test different Torx sizes to find the perfect match for your screws.

Another consideration is the pilot hole. Drilling a pilot hole reduces the risk of splitting wood or cracking other materials. The hole should match the screw's diameter. However, if the hole is too wide, the screw might not hold securely. Always double-check your measurements for a solid connection.

Maintenance Tips to Maximize the Lifespan of Stainless Torx Screws

When using stainless Torx screws, proper maintenance is crucial for longevity. Regular inspections help identify wear and tear. Check for corrosion, especially in humid environments. Ensure screws remain tight; loose screws can damage materials over time. If you notice any signs of rust, consider replacing them promptly.

Cleaning stainless Torx screws is essential. Use mild soap and water to remove dirt. Harsh chemicals can lead to corrosion. A soft brush works well for hard-to-reach areas. Sometimes, you may overlook the smallest details, leading to greater issues later. Be diligent with cleaning, particularly in outdoor projects.

Proper storage also enhances the lifespan of stainless screws. Keep them in a dry place. Avoid mixing different materials in storage. This can lead to confusion and incorrect usage. Remember, ignoring these simple steps may lead to problems you could have easily prevented. Care today ensures success tomorrow.

Related Posts

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project

-

Ultimate Guide to Stainless Torx Screws Tips for Optimal Performance and Use

-

2026 Top Stainless Carriage Bolt Uses and Benefits?

-

Understanding the Importance of Carriage Bolt Selection in Construction Projects

-

2025 Trends in Construction Fasteners: The Rise of Truss Head Carriage Bolts

-

How to Choose High Tensile Carriage Bolt for Your Project?