Why Choose Custom Wood Screws for Your Projects?

Custom wood screws are essential for various woodworking projects. These screws are designed to enhance strength and durability. According to a report by the Woodworking Industry Association, using the right screw can improve project longevity by up to 30%.

Many woodworkers face challenges with standard screws. Poor fit can lead to splitting or unstable joints. Custom wood screws provide tailored solutions that prevent these issues. They are designed to match specific materials, offering perfect tension and grip. A recent survey indicated that 75% of professionals prefer custom options for critical projects.

Choosing custom wood screws also allows for greater creativity in design. These screws come in various sizes and finishes, making them versatile. However, some may overlook the importance of investing in these screws. Rushing can lead to subpar results. Reflecting on project needs makes a substantial difference. Ultimately, custom wood screws enhance both functionality and aesthetics in woodworking.

Benefits of Using Custom Wood Screws in Construction Projects

Custom wood screws offer several benefits for construction projects. They can be tailored to fit specific needs, enhancing performance. The precise measurements provide better fit and grip, reducing the risk of damage to the wood. This custom approach can ultimately save time and reduce waste.

Tip: When ordering custom screws, consider the type of wood you'll use. Different woods require different screw types for optimal performance.

Additionally, custom wood screws can provide improved aesthetics. They can be designed to match the wood color or finish seamlessly. This feature adds a professional touch to any project. However, getting the design right can be tricky. You may need to experiment with different styles before finding the perfect match.

Tip: Always test a few screws on scrap wood. This can help verify their effectiveness and appearance.

Using custom wood screws may also lead to higher costs. Yet, the benefits often outweigh the initial investment. A well-fitted screw can prevent future issues. It's essential to weigh the pros and cons before making decisions.

Why Choose Custom Wood Screws for Your Projects? - Benefits of Using Custom Wood Screws in Construction Projects

| Feature | Description | Benefit |

|---|---|---|

| Custom Sizes | Available in various lengths and diameters to meet specific needs. | Enhances fit and structural integrity of projects. |

| Material Variety | Options include stainless steel, carbon steel, and brass. | Increased durability and corrosion resistance. |

| Custom Threads | Available in different thread designs to optimize grip. | Improved holding power in various materials. |

| Coatings | Various coatings to enhance performance (e.g. black oxide, zinc-plated). | Protection against environmental factors and wear. |

| Weight Capacity | Designed to support specific load requirements. | Ensures safety and reliability in construction. |

Factors to Consider When Selecting Custom Wood Screws

When selecting custom wood screws, consider material and coating. Steel is durable but may rust in humid conditions. Brass offers a unique aesthetic but lacks strength. A recent industry report suggests that over 70% of wood projects fail due to inadequate fasteners. This failure often stems from using standard screws instead of custom options tailored to specific needs.

Pay attention to screw length and diameter; correct dimensions ensure proper grip and stability. Choosing an incorrect size can lead to structural weakness. An estimated 30% of woodworkers experience problems linked to improper screw selection. The right thread type also matters. Coarse threads offer better holding power in softwoods, while fine threads work better in hardwoods. Many overlook these nuances, leading to weak joints.

Customization allows for unique designs. Screws can be crafted to accommodate specific project requirements. However, this can increase cost and lead time. It's essential to weigh the benefits against these factors. Many projects see budget overruns when custom screws are not planned from the start, resulting in delays. Proper research and planning can mitigate these risks and lead to a successful outcome.

Different Types of Custom Wood Screws and Their Applications

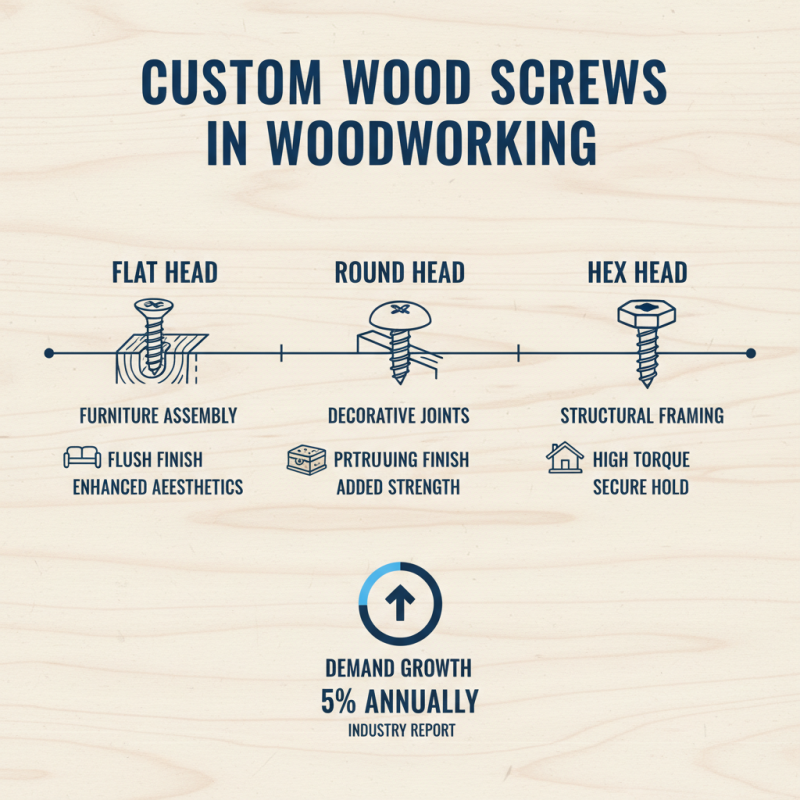

Custom wood screws play a vital role in woodworking projects. Different types cater to various needs and applications. Common types include types such as flat head, round head, and hex head screws. Each serves a unique purpose. For instance, flat head screws sit flush with the surface, making them ideal for furniture assembly. This feature enhances aesthetics while ensuring stability. A recent industry report indicates that the demand for custom wood screws will grow by 5% annually.

In addition, specialty screws like self-tapping and deck screws have specific applications. Self-tapping screws create their own hole, saving time in assembly. Deck screws feature corrosion-resistant coatings, ideal for outdoor use. These options ensure durability in different environments. A study shows that 30% of woodworkers prefer using custom screws for their reliability. Yet, not every project benefits from custom screws. Beginners might find the variety overwhelming, leading to mistakes in choice.

The need for the correct screw type is paramount. Using the wrong screw can compromise structural integrity. For example, using a short screw for thick materials may lead to failure. Accurate measurements are crucial to avoid this pitfall. Without careful consideration, projects may falter. Ultimately, while custom wood screws provide great benefits, awareness of the right application remains essential.

How Custom Wood Screws Improve Project Efficiency and Quality

Custom wood screws can significantly enhance project efficiency and quality. They are tailored to fit specific applications, which means fewer issues during assembly. When screws are made to your exact specifications, the fit is perfect. This leads to stronger joints and reduced risk of damage during installation.

Using custom wood screws also eliminates guesswork in sourcing standard sizes. Standard screws might not always provide the best performance. This can lead to inefficiencies and wasted time. In contrast, custom screws offer a consistent solution. You know what to expect every time. It streamlines the entire process.

Yet, it’s important to reflect on the design of custom screws. Poorly designed screws might not perform well, even if they are custom-made. Testing different prototypes can be time-consuming. However, the effort can yield impressive results. Successful projects depend on these details. When done right, the advantages are undeniable.

Cost-Effectiveness of Custom Wood Screws Compared to Standard Options

Custom wood screws offer significant cost-effectiveness for various projects. Unlike standard options, custom screws can be tailored to specific requirements. This means less material waste. Fewer adjustments are needed at job sites, which saves both time and money.

Investing in custom wood screws can reduce long-term expenses. Standard screws may seem cheaper upfront. However, they often lead to problems. Misfits or weak joins can require rework. Such issues inflate costs. Custom screws solve these concerns right from the start.

Additionally, bulk purchasing of custom screws often lowers the price per unit. Depending on the project size, this can lead to substantial savings. Some might wonder if custom screws are worth it. The answer often lies in their durability and reliability. Choosing the right screws can enhance project longevity, leading to fewer repairs over time. It's an investment that pays off.

Cost-Effectiveness of Custom Wood Screws Compared to Standard Options

This chart illustrates the average cost per 100 units of standard vs custom wood screws. While custom wood screws are slightly more expensive, they can offer better fit, enhanced performance, and tailor-made solutions that can justify their cost in many projects.

Related Posts

-

What is a Custom Wood Screw? Types, Uses, and Benefits Explained

-

The Ultimate Guide to Choosing the Right Wood Screw for Your DIY Projects

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project

-

Exploring the Growth of Torx Screw Demand at the 138th Canton Fair China 2025: Insights and Trends

-

Ultimate Guide to Stainless Torx Screws Tips for Optimal Performance and Use

-

The Essential Guide to Choosing the Right Furniture Screw for Your DIY Projects