Why You Should Choose Countersunk Head Bolts for Your Projects

When it comes to selecting fasteners for your projects, the choices can be overwhelming. However, one type of bolt that stands out for its unique design and functionality is the Countersunk Head Bolt. This innovative fastening solution is specifically engineered to provide not only a secure hold but also an aesthetically pleasing finish. The countersunk head design allows the bolt to sit flush with the surface of the material, minimizing obstruction and creating a smooth, clean appearance. This characteristic makes it particularly advantageous in applications where surface integrity is paramount.

Moreover, the versatility of Countersunk Head Bolts extends across various materials and industries, making them suitable for both professional and DIY projects. Whether you’re working with wood, metal, or plastic, these bolts can accommodate a range of applications while ensuring stability and strength. By choosing Countersunk Head Bolts, you are effectively enhancing the durability and visual appeal of your work. This introduction to the benefits and applications of Countersunk Head Bolts will provide you with the necessary insights to make an informed decision for your next project.

Understanding Countersunk Head Bolts and Their Design Features

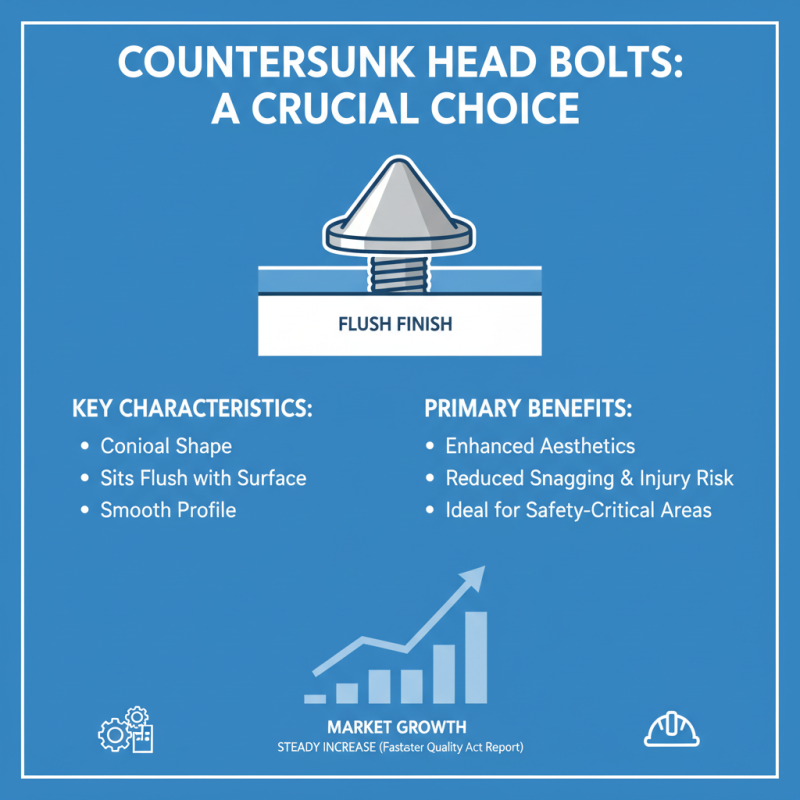

Countersunk head bolts are specially designed fasteners with a tapered head that allows them to be flush with the surface of the material they are installed in. This unique design feature not only enhances the aesthetics of a finished project by providing a smooth and clean appearance but also minimizes the risk of snagging or interference with other components. The countersunk design allows for a socket or wrench to easily access the bolt head without protruding above the surface, making it an ideal choice for applications where space is limited or where safety is a concern.

In addition to their visual appeal, countersunk head bolts provide significant advantages in structural integrity and fastening performance. The taper of the bolt head helps to distribute the load over a larger area, reducing the risk of material deformation. This feature is especially beneficial in applications involving wood or softer materials, where traditional bolt heads might create stress points or lead to damage. The design also facilitates a more secure fit, as the bolt can be tightened further into the material, ensuring that it stays firmly in place under various conditions. Overall, the thoughtful engineering of countersunk head bolts makes them a practical and versatile choice for a wide range of construction and assembly projects.

Advantages of Using Countersunk Head Bolts in Various Applications

Countersunk head bolts are increasingly favored in various applications due to their unique design and advantages. The countersunk shape allows the bolt to sit flush with the surface, making it ideal for scenarios where a smooth finish is essential. This feature prevents snagging while enhancing the overall aesthetic of the project. In industries such as construction, automotive, and furniture manufacturing, the use of countersunk bolts can significantly improve both functionality and appearance.

One of the main advantages of countersunk head bolts is their ability to provide a stronger grip in the materials they are fastened to. The conical shape distributes stress evenly, reducing the likelihood of stripping or loosening over time. This makes them particularly useful in high-load applications where safety and durability are paramount. Additionally, the countersunk design minimizes the risk of damage to the surrounding surface, making these bolts a smart choice for delicate finishes or materials.

Tips for choosing the right countersunk head bolts: First, ensure that the countersink angle matches the drill hole's angle to achieve a secure fit. Second, consider the material of the bolt, as high-strength options are available for specific applications. Finally, always check the load capacity and specifications to ensure that the bolts will perform optimally in your project. By following these tips, you can make the most of the advantages that countersunk head bolts offer.

Advantages of Using Countersunk Head Bolts in Various Applications

Comparing Countersunk Head Bolts to Other Bolt Types

When selecting fasteners for a project, understanding the differences in bolt types is crucial. Countersunk head bolts, known for their conical shape, are designed to sit flush with the surface they are fastened to, making them an ideal choice for applications where a smooth profile is essential. This characteristic not only enhances the aesthetic quality of a finished product but also minimizes the risk of snagging and injury in environments where safety is a concern. According to a report by the Fastener Quality Act, the market for countersunk bolts has seen a steady increase, indicating their growing preference in various industries, especially in manufacturing and construction.

In comparison to standard hex head bolts, countersunk head bolts distribute loads more evenly over a broader area, decreasing the likelihood of damage to materials they’re installed on. Test data shows that countersunk bolts exhibit superior shear strength, which is critical in structural applications. Additionally, while hex head bolts may offer ease of installation with traditional wrenches, countersunk designs allow for a cleaner installation that can be critical when factors such as aerodynamics or aesthetics are in play. Industry forecasts from the Industrial Fasteners Institute predict a continued growth in the use of countersunk head bolts, fueled by innovations in materials and engineering practices that prioritize durability and design integrity.

Installation Techniques for Countersunk Head Bolts

Countersunk head bolts are preferred in a variety of engineering and construction projects due to their unique installation techniques that enhance both aesthetics and functionality. When installing these bolts, it’s crucial to ensure that the countersink hole is accurately drilled to match the bolt’s head profile. This method not only allows the bolt to sit flush with the surface, minimizing protrusion, but also reduces the risk of snagging or interference with other components. According to a report by the American National Standards Institute (ANSI), proper installation of countersunk head bolts can improve the structural integrity of connections, which is vital in demanding applications such as aerospace and automotive industries.

When using countersunk head bolts, it’s essential to select the correct drill bit size and angle to create an effective countersink. A common tip is to use a drill bit with a 90-degree angle for most standard countersunk bolts. Additionally, using a pilot hole can significantly aid in aligning the bolt, ensuring a precise and secure fit. Statistics from the Mechanical Engineering Journal indicate that improperly installed bolts can lead to a 30% increase in material failure rates, underscoring the importance of proper installation techniques.

Lastly, always consider the material compatibility between the bolt and the surface it will be installed on. This can prevent corrosion and ensure a lasting installation. According to research published in the Journal of Materials Science, mismatched materials can compromise the tension and shear strength of the connection, leading to premature failures. Employing the correct installation techniques and careful material selection is key to optimizing the performance of countersunk head bolts in your projects.

Why You Should Choose Countersunk Head Bolts for Your Projects - Installation Techniques for Countersunk Head Bolts

| Project Type | Material | Countersunk Head Bolt Size | Installation Technique | Advantages |

|---|---|---|---|---|

| Furniture Assembly | Wood | M6 | Pre-drill holes, angle the drill for proper countersinking | Flush finish, no protruding parts |

| Automotive Assembly | Aluminum | M8 | Use torque specifications to avoid stripping | Improved aerodynamics, reduced drag |

| Electronics | Plastic | M2 | Controlled speed to prevent cracking | Secure attachment, aesthetic designs |

| Construction | Steel | M12 | Use washers for even load distribution | High strength, load-bearing capabilities |

Common Materials and Finishes for Countersunk Head Bolts

When selecting countersunk head bolts for your projects, understanding the common materials and finishes available is essential for achieving both functionality and aesthetics. Countersunk head bolts are typically manufactured from materials such as carbon steel, stainless steel, and alloy steel. According to a report by the Global Fasteners Market, stainless steel accounts for approximately 38% of the fastener market due to its excellent corrosion resistance and durability, making it a preferred choice in industries like construction and automotive.

In addition to the base materials, the finishes applied to countersunk head bolts can significantly affect their performance and appearance. Common finishes include zinc plating, which provides a layer of protection against rust and corrosion, and black oxide, which offers a sleek, matte finish that minimizes glare. Reports indicate that the demand for coated fasteners has surged, with a notable increase in projects requiring high corrosion resistance in harsh environments. Selecting the right combination of materials and finishes not only enhances the longevity of countersunk head bolts but also ensures that they meet specific project requirements efficiently.

Related Posts

-

Ultimate Guide to Choosing the Right Button Head Bolt for Your Project

-

The Essential Guide to Choosing the Right Furniture Screw for Your DIY Projects

-

2025 Top Trends in Furniture Bolt Technology for Modern Home Designs

-

Exploring the Benefits and Applications of Mushroom Head Carriage Bolts in Modern Construction

-

Exploring the Growth of Torx Screw Demand at the 138th Canton Fair China 2025: Insights and Trends

-

What is a Mushroom Head Screw? A Complete Guide to Types and Uses