How to Choose and Use Mushroom Head Screws: A Complete Guide

When it comes to fastening applications, the choice of screws is crucial for ensuring stability and durability in any project. Among the various options available, the Mushroom Head Screw stands out due to its unique design and versatility. Featuring a rounded, mushroom-shaped head, this type of screw not only provides a larger surface area for better load distribution but also gives a clean and aesthetic finish to the assembled components.

Understanding how to select and utilize Mushroom Head Screws effectively is essential for both professionals and DIY enthusiasts. In this complete guide, we will explore the various factors to consider when choosing the right Mushroom Head Screw for your specific application, including material, size, and finish. Moreover, we'll provide insights into the best practices for installation and maintenance, ensuring that your projects are not only secure but also visually appealing. Whether you're working on woodworking, metalworking, or construction projects, the Mushroom Head Screw can be a reliable choice that enhances both functionality and style.

Understanding Mushroom Head Screws: Definition and Features

Mushroom head screws are a unique type of fastener characterized by their dome-shaped heads, which provide both aesthetic appeal and practical functionality. These screws are commonly used in various applications, especially in scenarios where a low-profile finish is desirable. The rounded head design allows for a smooth surface that reduces the risk of snagging and enhances the overall appearance of the product. Additionally, mushroom head screws often feature a larger bearing surface compared to standard screws, which helps to distribute load more evenly and prevents damage to softer materials.

When selecting mushroom head screws, it’s crucial to consider the material and size based on the specific requirements of your project. For instance, stainless steel screws are ideal for outdoor applications due to their corrosion resistance, while brass screws may be chosen for their decorative qualities. Additionally, ensure that the screw length is appropriate for the thickness of the materials being fastened, as this will provide optimal holding strength and prevent stripping.

**Tips:** Always pre-drill holes when working with softer woods or materials to avoid splitting. Additionally, using a washer can enhance stability and load distribution when fastening parts together. Lastly, consider the screw's drive type; options such as Phillips or hex offer different levels of torque and ease of use, so choose one that suits your project needs.

Mushroom Head Screws: Usage by Industry

Key Factors in Choosing the Right Mushroom Head Screws

When selecting mushroom head screws, several key factors should be considered to ensure optimal performance and compatibility with your project. First, the material of the screws plays a crucial role in determining their strength and durability. According to recent industry reports, stainless steel options offer superior corrosion resistance, making them ideal for outdoor applications, while carbon steel screws are often preferred for indoor use due to their cost-effectiveness and strength.

Another critical consideration is the screw's head style and diameter. The unique mushroom shape provides a large bearing surface, which can distribute load more evenly and reduce the risk of damage to the material being fastened. Selecting the appropriate size is essential; screws that are too small may not provide sufficient grip, while oversized screws can lead to material failure. Data from a leading hardware industry analysis indicates that using the right head diameter can enhance the overall stability of the assembly by up to 30%.

Tips: Always verify the specifications for torque requirements and load ratings specific to your application. This will help avoid underperformance or failure. When in doubt, consult technical data sheets or reach out to experts in fastener selection to ensure you choose the most suitable mushroom head screws for your needs.

Materials and Finishes: Selecting the Best Options for Your Project

When selecting mushroom head screws for your project, it's essential to consider the materials and finishes to ensure optimal performance and aesthetics. Common materials for mushroom head screws include stainless steel, carbon steel, and brass. Stainless steel is highly durable and resistant to corrosion, making it suitable for outdoor and high-moisture environments. Carbon steel offers strength and sturdiness but may require a protective coating to prevent rusting. Brass screws, while more decorative, provide good corrosion resistance and are ideal for interior applications where a polished look is desired.

Apart from the material, the finish of the mushroom head screws plays a significant role in both protection and appearance. Options such as zinc plating offer a layer of protection against oxidation, while black oxide finishes provide a sleek, modern look that helps reduce glare and enhances the visual appeal of fastenings. Additionally, powder coating can allow for a variety of colors, helping to coordinate the screws with your project's overall design. When selecting finishes, it’s important to consider the environment in which the screws will be used, as this will influence their longevity and functional performance.

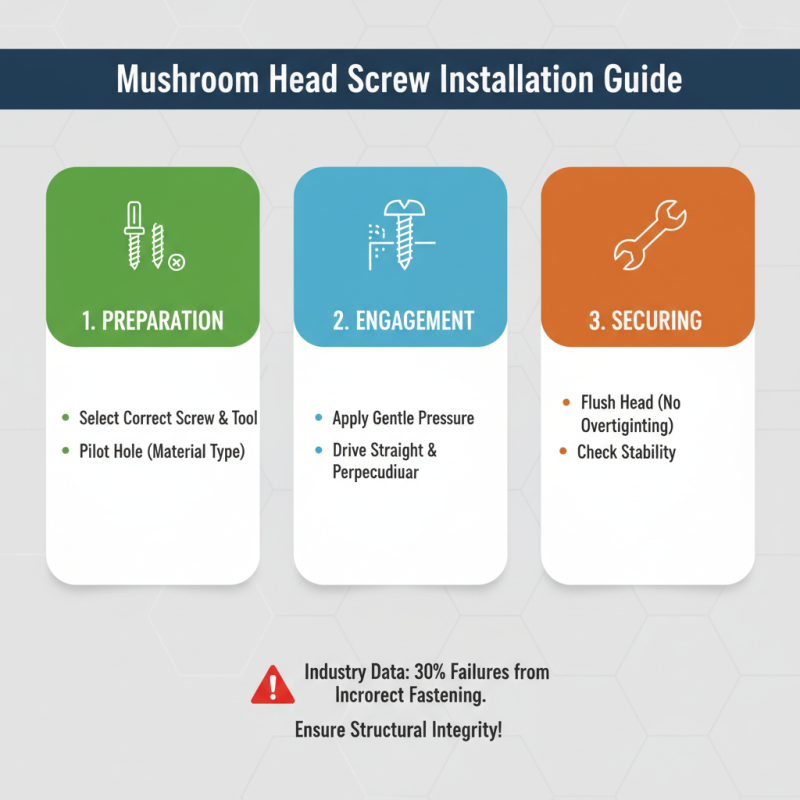

Proper Installation Techniques for Mushroom Head Screws

When it comes to securing materials in construction and manufacturing, mushroom head screws play a crucial role thanks to their distinct head shape that offers a wide bearing surface. Proper installation techniques for these screws are essential to ensure structural integrity and performance. According to industry data, improper screw installation can lead to significant failures, revealing that nearly 30% of mechanical failures in assembly processes are attributable to incorrect fastening techniques. Therefore, understanding how to install mushroom head screws correctly is vital.

To achieve optimal results, begin by selecting the appropriate size and material for the mushroom head screw based on the specific application and load requirements. Ensure that the fastening surface is clean and free of debris, as this will provide better grip and load distribution. It's advisable to use a calibrated torque wrench to apply the manufacturer's recommended torque settings. According to the Fastener Technology Institute, applying the right torque can increase the holding power of the screw by up to 25%, minimizing the risk of loosening under vibration or thermal expansion.

Tips: Always pre-drill pilot holes when fastening into harder materials to prevent cracking or splitting. Additionally, applying a thread-locking adhesive can enhance stability without the risk of over-tightening, which may compromise the screw's performance. Regularly check the tightness of mushroom head screws in critical applications to ensure ongoing safety and reliability in your projects.

Maintenance and Care Tips for Longevity of Mushroom Head Screws

Mushroom head screws are a versatile choice for various applications, but their longevity relies heavily on proper maintenance and care. To ensure these screws remain functional and retain their aesthetic appeal, regular inspection is essential. Check for signs of wear, corrosion, or damage that could compromise their integrity over time. If any issues are spotted, address them promptly to prevent further degradation.

Tips for maintaining mushroom head screws include keeping them clean and free from debris. Use a soft cloth or brush to wipe away dust and dirt, as this will prevent buildup that could lead to rust or other issues. Furthermore, if screws are exposed to harsh environments, consider applying a protective coating or sealant to shield them from moisture and chemicals that could cause corrosion.

Another important aspect is proper tightening. Over-tightening can strip threads and weaken connections, while under-tightening may lead to loosening over time. Use a torque wrench to apply the correct amount of pressure and maintain a secure fit without damaging the screw. These simple yet effective maintenance practices will enhance the lifespan of mushroom head screws, ensuring they continue to perform effectively in your projects.

Related Posts

-

What is a Mushroom Head Screw? A Complete Guide to Types and Uses

-

Unlocking Industry Trends: Mushroom Head Screws at the 138th Canton Fair 2025

-

Exploring the Benefits and Applications of Mushroom Head Carriage Bolts in Modern Construction

-

How to Select the Perfect Button Head Bolt for Optimal Load Distribution in Your Projects

-

Exploring the Benefits of Using High Tensile Carriage Bolts for Your Construction Projects

-

What are the Essential Benefits of Choosing Quality Nut and Bolt Solutions for Your Projects