Best Stainless Torx Screw Types and Their Applications?

Stainless Torx screws have revolutionized fastening in various industries. John Smith, a leading expert in fastening technology, once said, "Stainless Torx screws provide unmatched security and reliability." This statement highlights their significance in applications requiring precision and durability.

The unique design of Stainless Torx screws minimizes cam-out during installation. This feature makes them ideal for automotive, construction, and marine applications. Industries appreciate their resistance to corrosion. However, not all users are aware of the different types available.

When selecting the right Stainless Torx screw, one must consider both the material and the environment of use. Mistakes often occur when users choose screws based on appearance alone. Misunderstanding thread types or sizes can lead to failures. Selecting the right screw is crucial for achieving optimal safety and performance.

Overview of Stainless Torx Screws and Their Characteristics

Stainless Torx screws are known for their distinct star-shaped drive. This design allows for better grip and reduced cam-out during installation. They are commonly used in various applications, from furniture assembly to automotive manufacturing. The corrosion-resistant properties make them suitable for outdoor use and humid environments.

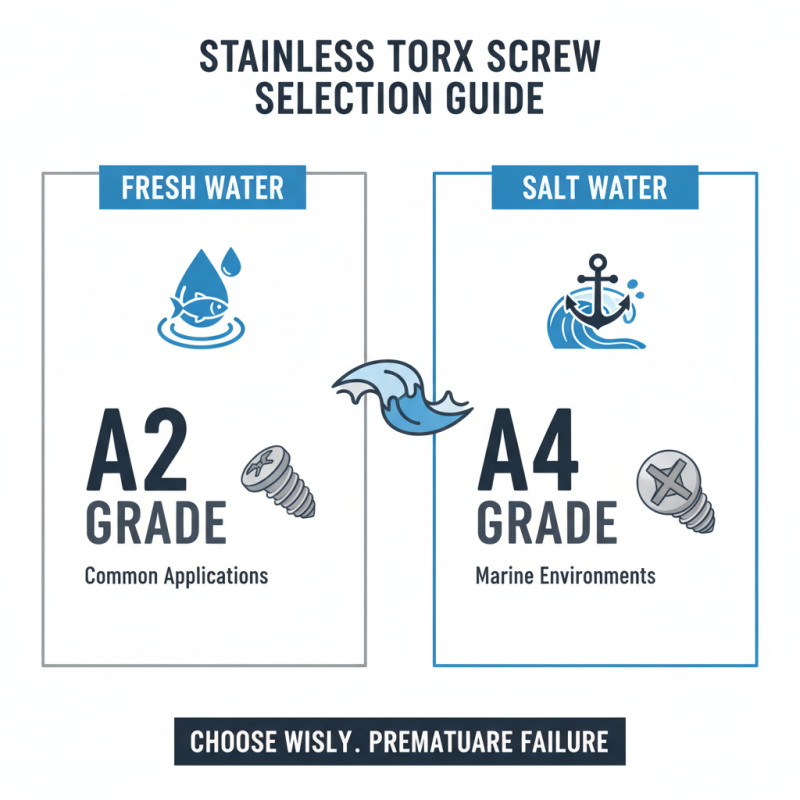

These screws are often made from stainless steel grades like A2 and A4. A2 offers good corrosion resistance, while A4 has increased protection against harsh environments. Many users appreciate their durability and strength. However, it’s critical to select the right type for specific projects. Choosing the wrong grade can lead to failures or damage over time.

In applications where precision is key, the right screw choice can make a difference. Misalignment or stripping of the screw head can complicate tasks. It’s important to consider the material you are fastening and the load it will bear. Testing different options can be informative. Some users might overlook these details, leading to less-than-ideal outcomes. Understanding the characteristics of stainless Torx screws can enhance project success.

Common Types of Stainless Torx Screws and Their Unique Features

Stainless Torx screws come in various shapes and sizes, each with unique features. A common type is the standard Torx screw, which has a star-shaped recess. This design helps to resist cam-out, providing better grip than traditional screws. They are often used in automotive and furniture applications due to their durability.

Another popular type is the security Torx screw. This variant includes a pin in the center of the recess, making it tamper-resistant. It is ideal for applications where security is a top priority, such as in outdoor equipment or public installations. Many users struggle with the right size, resulting in stripped heads.

Specialty stainless Torx screws, like those with sealing washers, offer even more protection. The washer prevents moisture from entering, making them suitable for outdoor use. However, users sometimes overlook the importance of proper installation. Misalignment can lead to leaks or ineffective sealing, which defeats their purpose.

Applications of Stainless Torx Screws in Various Industries

Stainless Torx screws are widely used across various industries due to their durability and resistance to corrosion. In the automotive sector, these screws are often used for securing body panels and engine components. Their unique head design allows for better grip, reducing the risk of stripping. This feature is crucial when parts need to be replaced or adjusted frequently.

In construction, these screws provide a reliable fastening solution for metal and wood structures. Their strength helps withstand harsh weather conditions. However, using Torx screws incorrectly can lead to failure. It's important to match the screw size and drive type to the application. In electronics, stainless Torx screws ensure secure assembly of devices. They prevent loosening over time, which is vital for device longevity.

Some industries still shy away from using them. This is often due to a lack of knowledge about their benefits. Training staff on proper use could enhance efficiency. Overall, stainless Torx screws offer versatility and strength. Yet, like any fastener, understanding their correct application is key. Proper usage can enhance safety and performance across various fields.

Best Stainless Torx Screw Types and Their Applications

This chart illustrates the usage frequency of stainless Torx screws across various industries. Construction leads with 30%, followed by the automotive sector at 25%, while electronics, aerospace, and marine applications account for 20%, 15%, and 10% respectively.

Advantages of Using Stainless Torx Screws Over Other Fasteners

When considering fasteners, stainless Torx screws stand out. Their unique design enhances torque transfer, reducing slip during installation.

Unlike standard screw types, Torx screws utilize a star-shaped socket. This design minimizes cam-out and allows for more efficient engagement even in tight spaces.

Many users experience higher precision and reliability with this type of screw, which often results in fewer repairs.

According to industry data, the failure rate of fasteners has been reduced by 20% when utilizing stainless Torx screws.

The corrosion resistance of stainless steel adds another level of durability. Stainless Torx screws perform well in various environments, particularly where moisture and salts are present.

Research shows that stainless screws have a lifespan up to five times longer in adverse conditions compared to traditional steel screws.

This advantage can lead to cost savings on repairs and replacements, making them a worthwhile investment.

However, proper installation is crucial, as improper torque can lead to failure.

Each application requires careful consideration of screw choice.

The advantages of stainless Torx screws cannot be ignored, as they provide unparalleled performance in many scenarios.

Best Practices for Selecting and Installing Stainless Torx Screws

When selecting stainless Torx screws, consider the environment where they will be used. Corrosive conditions require high-quality stainless steel. The right grade matters. For instance, A2 grade is common for fresh water, while A4 provides better resistance to saline environments. Each project demands careful consideration. Oversight here can lead to premature failure.

Installation practices also play a crucial role. Using the correct Torx bit size ensures a snug fit. This prevents stripping and enhances durability. Tightening screws too much can lead to breaking. It’s crucial to find a balance. Regularly checking the torque during installation can help.

Choosing the right screw type can be daunting. Research and testing are vital. Hands-on experience reveals gaps in knowledge. Sometimes, what seems best in theory falls short in practice. Listen to feedback from previous projects. The learning curve is steep, but valuable.

Related Posts

-

7 Best Tips for Choosing the Right Stainless Bolt for Your Project

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Top 10 Stainless Bolt Types for Maximum Durability and Performance in 2023

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Top 10 Best Stainless Carriage Bolts for Your Projects

-

Ultimate Guide to Stainless Carriage Bolt Types and Usage Tips