Top 10 Best Stainless Carriage Bolts for Your Projects

In the realm of construction and DIY projects, the choice of fasteners is crucial to ensuring the structural integrity and longevity of assembled structures. Among the various types of fasteners, the stainless carriage bolt stands out due to its unique design and exceptional resistance to corrosion, making it an ideal choice for both indoor and outdoor applications. According to industry research conducted by the Fastener Industry Coalition, the demand for stainless steel fasteners has seen a significant increase, with projections indicating a continuous upward trend as the construction sector emphasizes durability and sustainability.

Stainless carriage bolts are particularly favored for their ability to provide a secure, stable connection in woodworking and metalworking applications. The smooth, rounded head design allows for easy installation, while the square neck prevents the bolt from turning when tightened. Reports from the Stainless Steel Industry Association highlight that stainless steel's inherent properties, including strength and resistance to rust, have made it the preferred material in high-stress environments like marine and construction sites. As projects increasingly prioritize resilience, the adoption of stainless carriage bolts not only enhances performance but also aligns with the industry's commitment to quality and longevity.

In this guide, we will explore the top 10 best stainless carriage bolts available, scrutinizing their features and benefits to assist you in selecting the optimal fasteners for your projects. Whether you're embarking on a small DIY task or a large-scale construction endeavor, understanding the advantages of stainless carriage bolts is essential for achieving durable results.

Understanding Carriage Bolts and Their Applications

Carriage bolts, often noted for their distinctive rounded heads and square neck designs, are a vital element in various construction and woodworking projects. These bolts excel in providing a secure fastening solution where a smooth finish is required on one side of a surface. Their design allows the square neck to embed into the material, preventing the bolt from turning when a nut is tightened. According to data from the Fastener Quality Act (FQA), the use of high-quality stainless steel carriage bolts significantly enhances durability, making them resistant to corrosion, particularly in outdoor environments where moisture exposure is a concern.

Understanding the applications of carriage bolts can lead to more efficient project management. Typically used in wood-to-wood connections and when joining wooden structures to metal, these bolts excel in providing strength while minimizing the risk of splitting the wood. A report from the American Fastener Manufacturers Association (AFMA) highlights that the demand for carriage bolts has surged by 15% in construction projects over the last year, demonstrating their growing importance in engineering and design frameworks. This rise emphasizes the need for construction professionals to consider the specific type of carriage bolt, particularly those made from stainless steel, which offer longevity and performance.

Tips: Always pre-drill holes slightly larger than the diameter of the bolt to allow for easy insertion and to minimize stress on the wood fibers, ensuring a tight and secure fit. Additionally, for applications exposed to the elements, consider using grade 316 stainless steel bolts for maximum corrosion resistance, as they can withstand harsher environments compared to lower grades.

Top 10 Best Stainless Carriage Bolts for Your Projects

| Bolt Size (Diameter x Length) | Material | Head Type | Finish | Weight (lbs) | Best Use Case |

|---|---|---|---|---|---|

| 1/4" x 2" | Stainless Steel | Round | Plain | 0.15 | Wood Projects |

| 3/8" x 3" | 304 Stainless Steel | Square | Polished | 0.25 | Structural Applications |

| 5/16" x 4" | 316 Stainless Steel | Round | Brushed | 0.30 | Marine Applications |

| 1/2" x 6" | Stainless Steel | Square | Plain | 0.75 | Heavy-Duty Construction |

| 3/16" x 2" | A2 Stainless Steel | Round | Electropolished | 0.10 | Lightweight Applications |

| 1/4" x 3" | Carbon Steel | Round | Hot-Dipped Galvanized | 0.20 | Outdoor Furniture |

| 3/8" x 5" | 304 Stainless Steel | Square | Smooth | 0.50 | Machinery Assembly |

| 1/2" x 4" | A4 Stainless Steel | Round | Natural | 1.00 | Marine Equipment |

| 5/16" x 3" | Stainless Steel | Square | Oxide Coated | 0.35 | Furniture Assembly |

| 3/8" x 2" | 304 Stainless Steel | Round | Polished | 0.20 | Decking |

Key Features to Consider When Choosing Stainless Carriage Bolts

When selecting stainless carriage bolts for your projects, several key features must be considered to ensure optimal performance and longevity. First and foremost, the material grade of the stainless steel is crucial. Generally, bolts made from 18-8 stainless steel are suitable for most outdoor and marine applications due to their excellent corrosion resistance. However, for more extreme environments, grade 316 stainless steel may be the better choice, as it offers enhanced protection against corrosion caused by saltwater and other harsh chemicals.

Another important feature to look at is the bolt's head design and size. Stainless carriage bolts typically have a rounded head with a square neck, which helps prevent spinning during installation. Ensure the head size matches your tooling to facilitate easy installation without slipping or stripping. Additionally, consider the length and diameter of the bolt, as this will affect its ability to secure materials together effectively. Proper sizing is essential to maintain structural integrity in the projects you are undertaking, whether in woodworking, construction, or furniture making.

Top 10 Recommendations for High-Quality Stainless Carriage Bolts

When it comes to construction and DIY projects, the quality of the materials you use can significantly impact the final outcome. Stainless carriage bolts stand out as a popular choice due to their durability and resistance to corrosion, making them ideal for both indoor and outdoor applications. When selecting stainless carriage bolts, it's vital to consider factors such as the grade of stainless steel, the length and diameter of the bolts, and whether they come with suitable nuts and washers for optimal performance.

In this guide to high-quality stainless carriage bolts, we present ten top recommendations that cater to various project needs. Each option excels in features like tensile strength and finish, ensuring you have reliable hardware at your disposal. From lightweight tasks to more heavy-duty applications, you can find suitable carriage bolts that offer exceptional performance and longevity.

By choosing high-quality materials, you're not only investing in the longevity of your projects but also ensuring a secure and stable structure that can withstand the test of time.

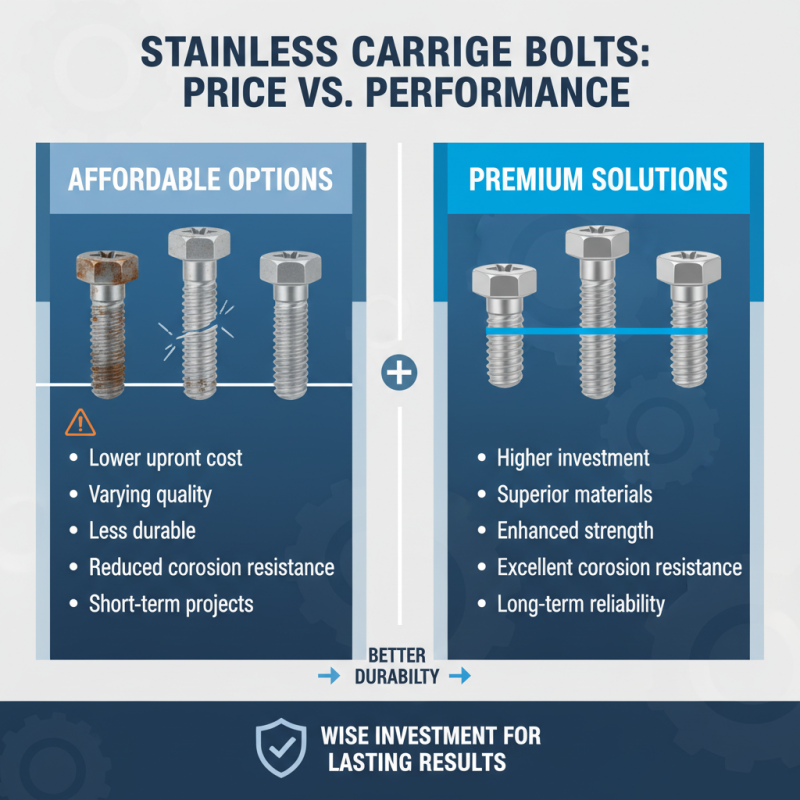

Comparative Analysis of Pricing and Performance of These Bolts

When embarking on projects that require reliable fastening solutions, the selection of stainless carriage bolts is crucial. A comparative analysis of various products highlights significant differences in pricing and performance that can impact the effectiveness of your final outcome. Many affordable options might seem appealing at first, but their quality can vary greatly. It's essential to evaluate the materials used, the strength of the bolts, and their corrosion resistance. Higher-priced bolts often offer better durability and performance under stress, making them a wise investment for long-term projects.

Tips for selecting the right carriage bolts include assessing the specific requirements of your project. Consider the load-bearing capacity you need and the environment in which the bolts will be used. For outdoor projects, choosing bolts with enhanced corrosion resistance is vital to ensure longevity. Additionally, inspect the thread quality and the finish of the bolts, as these factors can significantly influence their performance. Making a well-informed choice based on these criteria will ultimately save time and money in the long run.

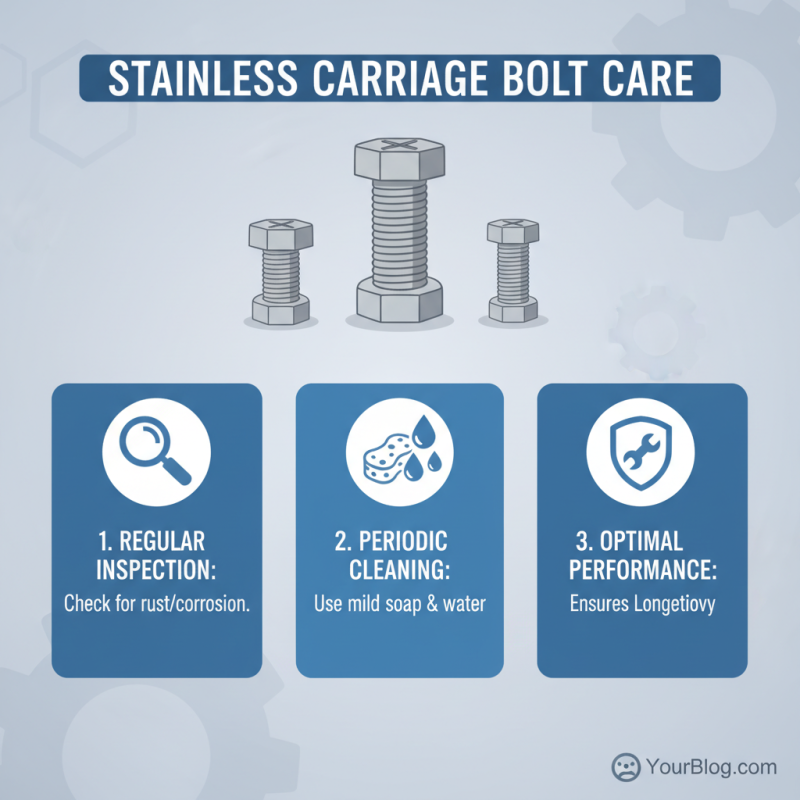

Maintenance Tips for Longevity of Stainless Carriage Bolts

Stainless carriage bolts are renowned for their strength and durability, making them ideal for a variety of projects. However, to ensure their longevity and maintain optimal performance, proper maintenance is essential. Regular inspection is key; check for signs of rust or corrosion, especially in outdoor applications. Cleaning the bolts periodically with a mild detergent and water can help remove any build-up that could lead to deterioration over time.

Another important aspect of maintaining stainless carriage bolts is ensuring they are installed correctly. Over-tightening can lead to stress fractures, while under-tightening may cause them to loosen with use. It’s advisable to use a torque wrench to achieve the recommended tension during installation. Additionally, consider applying a protective lubricant to the threads, which can help reduce friction and prevent the bolts from seizing.

Lastly, storing stainless carriage bolts in a dry environment will prevent moisture accumulation, which is a common cause of corrosion. Keeping them organized in a toolbox can also prevent physical damage. Following these simple maintenance tips will not only extend the life of your stainless carriage bolts but also enhance the overall safety and reliability of your projects.

Related Posts

-

7 Best Tips for Choosing the Right Stainless Bolt for Your Project

-

5 Essential Tips for Choosing the Right Truss Head Carriage Bolt for Your Project

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

Top 10 Stainless Bolt Types for Maximum Durability and Performance in 2023

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

How to Choose the Right High Tensile Carriage Bolt for Your Project Needs