Top 10 Benefits of Using Square Neck Bolts Today?

In today's fast-paced construction and manufacturing industries, choosing the right fastening solutions is crucial. One such option gaining popularity is the Square Neck Bolt. This distinctive hardware offers several advantages over traditional fasteners. Their unique design allows for a more secure grip, reducing the chance of loosening over time.

Square Neck Bolts can be used in various applications, from heavy machinery to furniture assembly. The functionality they provide is noteworthy. However, some may overlook their potential. Many assume standard bolts are sufficient. Yet, this assumption might lead to complications down the line. Using Square Neck Bolts can enhance stability and longevity in projects.

While they are not a one-size-fits-all solution, their benefits are substantial. It's important to assess if they meet specific project needs. Every choice has its pros and cons. Ultimately, the decision to use Square Neck Bolts can positively impact efficiency and durability in construction.

Advantages of Square Neck Bolts in Modern Engineering Applications

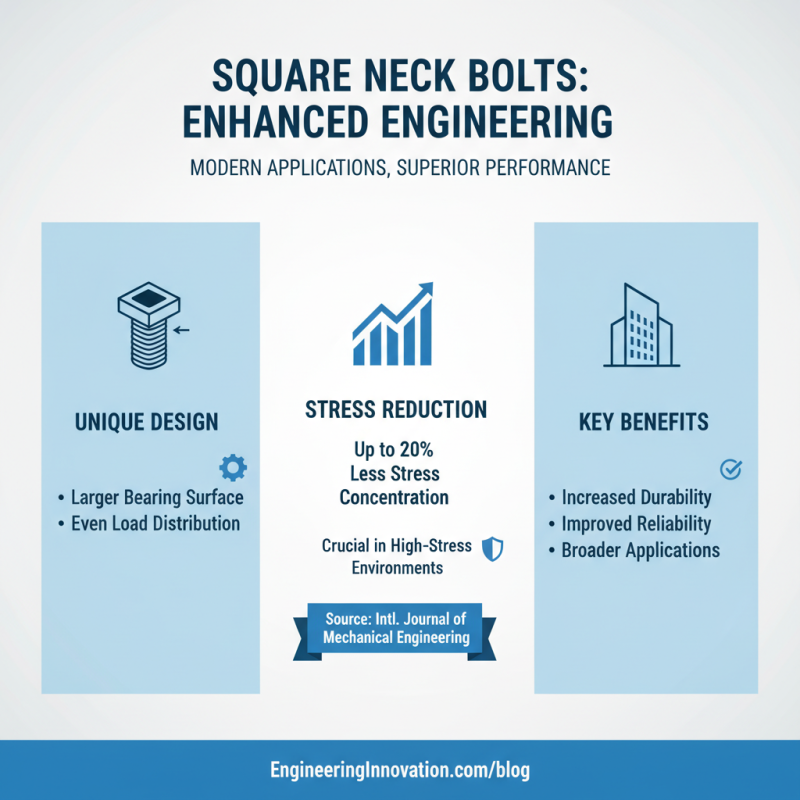

Square neck bolts are gaining traction in modern engineering applications. Their unique design provides a larger bearing surface. This design helps distribute load more evenly. A report from the International Journal of Mechanical Engineering shows that using square neck bolts can reduce stress concentrations by up to 20%. This is crucial in high-stress environments.

In addition, square neck bolts are easier to install. The square neck prevents rotation during tightening. This means workers can apply consistent force. A study conducted by the American Society of Mechanical Engineers highlights that this design reduces installation time by approximately 30%. However, engineers must consider certain limitations. Square neck bolts may not fit all environments or applications. In extreme conditions, alternative fastening methods might perform better. While they offer distinct advantages, it’s vital to assess the specific needs of each project.

Enhanced Stability: How Square Neck Bolts Improve Structural Integrity

Square neck bolts offer unique advantages in enhancing stability for various structures. Their distinctive design allows them to fit snugly into designated spaces. By preventing rotation, square neck bolts ensure a firm grip. This can lead to improved structural integrity in any assembly. When subjected to tension, these bolts can hold their place effectively, distributing loads evenly.

In construction, the precise placement of square neck bolts can be pivotal. They stabilize joints and connections that bear significant weight. A well-constructed joint can mean the difference between a sturdy framework and a shaky one. However, improper installation can compromise their benefits. Inadequate torque can lead to failures, initiating a reflection on best practices. Regular inspections are essential to maintain functionality and safety.

When considering design approaches, there are factors to weigh. Square neck bolts may simplify assembly, but they require specific tools for installation. Sometimes they can be over-engineered for lightweight applications. Yet, when used appropriately, they enhance safety and durability. Artists of construction must continue to adapt and reflect on their methods. The pursuit of strength should always account for evolving construction challenges.

Ease of Installation: The User-Friendly Design of Square Neck Bolts

Square neck bolts have gained popularity due to their user-friendly design. One of the key advantages of these bolts is their ease of installation. The square neck fits snugly into a pre-drilled hole, preventing it from spinning during tightening. This simple feature helps users save time and frustration. Many users enjoy this streamlined process.

Tip: When working with square neck bolts, always ensure your tools are compatible. A well-fitting tool can enhance the installation experience. Also, consider using a washer for added stability. This can be especially important in high-stress applications.

Another point worth noting is how the square neck provides a better grip compared to hexagonal counterparts. The broad surface area allows for even torque distribution. This reduces the chances of damaging the bolt. Nonetheless, it's essential to be mindful of overtightening. Too much pressure can compromise the integrity of the materials involved.

Tip: Regularly inspect your installations to ensure safety. Minor adjustments may be necessary over time. A well-maintained setup leads to better long-term performance.

Cost-Effectiveness: Maximizing Value with Square Neck Bolt Use

The cost-effectiveness of square neck bolts is noteworthy. These fasteners provide a robust solution with efficient functionality. According to industry research, square neck bolts can reduce installation time by up to 30%. This efficiency translates directly into labor cost savings. Less time on the job site means lower overall project expenses.

Data from the Fastener Quality Act indicates that using the right bolts increases structural integrity. Stronger connections lead to fewer failures, which can be costly. The prevention of these failures can result in savings of approximately 15% in maintenance and repair costs over time. Even minor failures can disrupt operations and impact budgets significantly.

However, the initial costs of square neck bolts might be higher than some alternatives. Sometimes, companies hesitate to invest upfront. This hesitation can lead to missed opportunities for savings in the long run. Choosing fasteners based solely on initial price can be shortsighted. Long-term value often outweighs the initial investment, making square neck bolts a wise choice.

Versatility: Applications of Square Neck Bolts Across Different Industries

Square neck bolts have gained popularity across various industries due to their unique design and versatility. They provide excellent grip and stability, making them suitable for diverse applications. Construction, furniture assembly, and automotive manufacturing are just a few areas where they shine. These bolts are often used in conjunction with different materials, increasing their adaptability. The square neck prevents rotation during installation, ensuring a secure fit every time.

Tips for using square neck bolts: always choose the right size for your project. Oversized bolts can weaken structures, while undersized may not secure properly. When installing, check for compatibility with your materials. Square neck bolts fit snugly against wood or metal, reducing the risk of movement.

In some cases, users may overlook the importance of a quality bolt. Not all square neck bolts are created equal. Poor-quality bolts can lead to failures. Be wary of cheaper options that may not perform well under stress. Always make informed choices to ensure durability and safety in your applications.

Top 10 Benefits of Using Square Neck Bolts Today

| Benefit | Description | Applications | Industry |

|---|---|---|---|

| High Load Capacity | Designed to support significant weights and resist shear stress. | Construction, Heavy Machinery | Engineering, Manufacturing |

| Reduced Vibration | Minimizes loosening during operation due to vibration. | Automotive, Aerospace | Transportation, Aircraft Manufacturing |

| Ease of Installation | Simple to install with standard tools, reducing labor costs. | General Maintenance, Assembly | Maintenance, Fabrication |

| Durability | Resists corrosion and wear, leading to longer service life. | Outdoor Structures, Marine Applications | Construction, Shipbuilding |

| Variety of Sizes | Available in multiple sizes to suit various needs. | Custom Projects, Specialty Equipment | Manufacturing, Custom Fabrication |

| Tight Grip | Square neck prevents rotation, providing a secure connection. | Structural Connections, Machinery | Construction, Industrial Equipment |

| Aesthetic Appeal | Enhances the visual aspect of exposed fasteners. | Furniture, Decorative Structures | Interior Design, Architecture |

| Cost-Effective | Provides good performance at a competitive price point. | Budget Projects, Mass Production | Manufacturing, Construction |

| Compatibility | Works well with various materials and joining methods. | Mixed-Material Structures, Assemblies | Innovative Engineering, Research |

Related Posts

-

7 Compelling Reasons Why Square Neck Bolts Are Essential for Your Projects

-

Top 10 High Tensile Carriage Bolt Benefits and Uses for Your Projects

-

2025 Guide: How to Choose the Best Furniture Fasteners for Your Projects

-

How to Choose High Quality Carriage Bolts for Your Projects in 2025

-

7 Best Button Head Bolt Options for Ultimate Performance

-

The Essential Guide to Choosing the Right Furniture Screw for Your DIY Projects