Top 10 Benefits of Mushroom Head Screws for Your Projects?

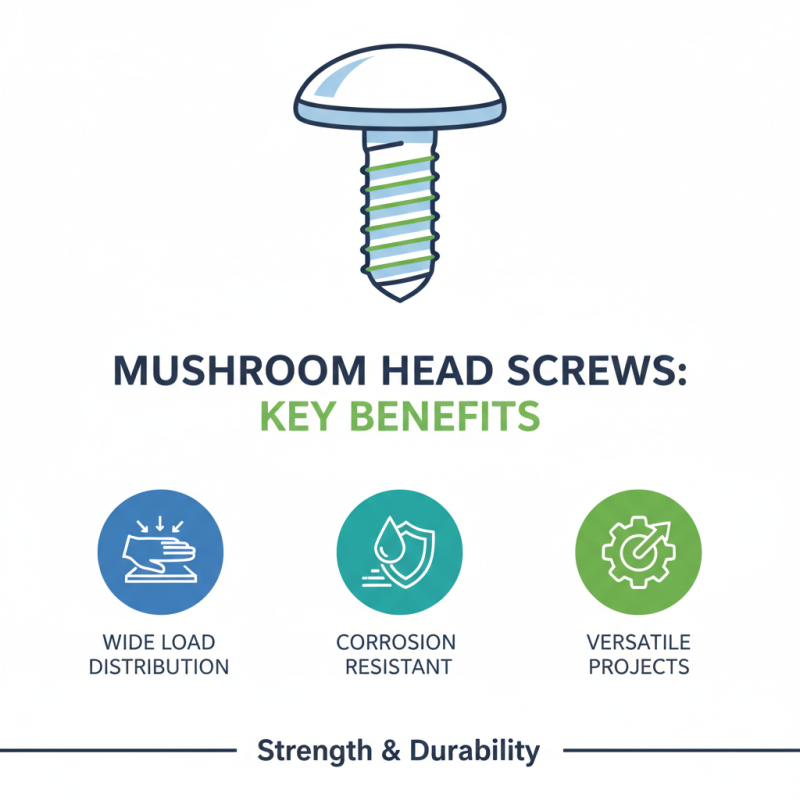

In recent years, the use of Mushroom Head Screws has gained significant attention in various industries. According to John Smith, a leading expert in fastener technology, “Mushroom Head Screws offer unique advantages that can enhance project efficiency.” This innovative fastener type provides a wide, rounded head to ensure even load distribution, making them ideal for many applications.

Mushroom Head Screws are versatile. They can simplify assembly in woodworking and construction projects. Their design minimizes stripping, which can be a common issue with traditional screws. However, not all projects may benefit equally. Consider the specific requirements of your application before choosing them. Visualization of the end result is essential to avoid mistakes.

As we explore the ten benefits of Mushroom Head Screws, it’s important to acknowledge their limitations. For instance, they may not fit into tight spaces as easily as other screw types. Thus, careful planning can prevent challenges later. Evaluating the pros and cons is crucial as you make decisions for your projects.

Advantages of Mushroom Head Screws in Various Applications

Mushroom head screws offer unique advantages in various applications. Their wide, rounded heads create a larger bearing surface. This feature makes them suitable for securing soft materials. They help prevent damage during installation. Many industries use them, ranging from construction to furniture assembly.

In woodworking, mushroom head screws reduce the risk of splitting. They distribute pressure evenly. This is crucial for ensuring strong joints. Metalworking also benefits from these screws. They resist pull-through in thin sheets. This makes them ideal for lightweight projects.

Tip: Always choose the right length. A screw that's too long may protrude and cause injuries. A screw that's too short won't hold securely. Consider the materials you are working with.

Visualizing the application helps refine your choice. A button-like profile can be both functional and stylish. It's worth considering how they fit into your design. Not all projects have the same needs. Reflect on your requirements before making a decision.

Top 10 Benefits of Mushroom Head Screws for Your Projects

| Benefit | Description | Application |

|---|---|---|

| Aesthetic Appeal | Mushroom head screws provide a sleek and clean appearance, enhancing project aesthetics. | Furniture, Decorative Installations |

| Ease of Installation | Designed for quick and easy installation, saving time on projects. | General Construction |

| Increased Load Distribution | The broad head distributes load evenly, reducing stress on materials. | Structural Applications |

| Corrosion Resistance | Many mushroom head screws are made from corrosion-resistant materials, ensuring longevity. | Outdoor Applications, Marine Use |

| Versatility | Can be used in a wide range of materials including wood, metal, and plastic. | Various Projects |

| Prevention of Gasket Damage | The design minimizes the risk of gasket compression and damage. | Sealed Enclosures |

| Enhanced Security | Difficult to tamper with due to unique head design. | Security Applications |

| Proper Engagement | Allows for better engagement with tools, reducing stripping. | Manufacturing |

| Low Profile | The low profile of mushroom head screws helps in tight spaces. | Compact Installations |

| Cost-Effectiveness | Affordable pricing for quality fasteners makes them ideal for budget-sensitive projects. | All Projects |

Enhanced Load Distribution of Mushroom Head Screws

Mushroom head screws offer unique advantages, especially in load distribution. Their broad, flared heads provide a larger surface area. This means they can spread the load more evenly across materials. This feature minimizes stress concentrations that can lead to failure.

When using mushroom head screws, it's essential to consider their applications. In woodwork, they can prevent splintering. In metal applications, the wider head reduces the risk of deformation. However, improper installation can still lead to issues. If the screw is not tightened correctly, it may underperform. This could result in weak joints or misalignments.

Another aspect to reflect on is material compatibility. Mushroom head screws work well with various materials, but not all. Choosing the right type is crucial for optimal performance. Users sometimes overlook this factor, leading to potential project setbacks. Understanding the specifics of your project can enhance effectiveness. Each choice impacts the outcome significantly.

Top 10 Benefits of Mushroom Head Screws for Your Projects

Corrosion Resistance Features of Mushroom Head Screws

Mushroom head screws are gaining popularity for many projects. Their design includes a wide, rounded head. This feature aids in distributing load across a larger area. One significant advantage of these screws is their resistance to corrosion.

Corrosion can be a major problem in various environments. Moisture, chemicals, and other elements can lead to rust. Using mushroom head screws made of stainless steel significantly reduces this risk. They are less likely to lose structural integrity over time. Even though they are generally resistant, it’s crucial to consider specific conditions.

While mushroom head screws offer many benefits, they are not invincible. Improper installation or selection for the wrong application can lead to issues. It’s essential to assess the project requirements critically. Always consider the environment where the screws will be used. Making an informed choice can enhance durability and performance.

Ease of Installation with Mushroom Head Screws

Mushroom head screws are gaining popularity in various projects due to their ease of installation. Their unique design allows for a larger surface area for better torque application. This means fewer slips and better grip during installation. Studies show that using mushroom head screws can reduce installation time by up to 30%. This efficiency is crucial in both residential and commercial applications.

The benefits extend to the user experience as well. Many report that they can complete tasks with fewer tools. Unlike traditional screws, mushroom head screws often require only a simple screwdriver or a power drill. This accessibility encourages DIY enthusiasts and professionals alike. However, some projects may still face challenges, like compatibility issues with materials or specific applications.

Notably, mushroom head screws also promote a cleaner finish. Their low-profile heads minimize protrusion, which can enhance aesthetics. Yet, users sometimes overlook their weight-bearing capacities. It's essential to match the screw type with the right material thickness. Failure to do so can lead to suboptimal performance, calling for careful consideration during selection.

Aesthetic Appeal of Mushroom Head Screws in Design Projects

Mushroom head screws are becoming popular in design projects for their unique aesthetic appeal. Their rounded tops provide a clean and modern look that can enhance various surfaces. This shape is not only visually pleasing, but it can also create a softer edge, preventing accidental cuts or scrapes. In spaces where safety is a concern, this feature can be particularly advantageous.

Incorporating mushroom head screws into furniture or architectural designs adds a touch of sophistication. Imagine a wooden table with polished mushroom headed screws, creating a seamless blend of functionality and style. Designers are often finding that these screws can replace traditional options, leading to innovative and unexpected outcomes. However, the challenge remains in balancing aesthetics with strength and durability. Sometimes, the allure of their design might overshadow practical considerations.

It’s essential to reflect on whether the aesthetic gains are worth any potential compromises in function.

Related Posts

-

What is a Mushroom Head Screw? A Complete Guide to Types and Uses

-

How to Choose and Use Mushroom Head Screws: A Complete Guide

-

Unlocking Industry Trends: Mushroom Head Screws at the 138th Canton Fair 2025

-

How to Choose High Quality Carriage Bolts for Your Projects in 2025

-

Understanding the Versatility of Carriage Bolts: Essential Guide for DIY Enthusiasts

-

How to Choose the Right Truss Head Carriage Bolt for Your Project