2025 Guide: How to Choose the Best Furniture Fasteners for Your Projects

In the ever-evolving world of furniture construction and design, the choice of the right furniture fastener can significantly impact both the structural integrity and aesthetic appeal of end products. According to a recent report by the International Wood Products Association, nearly 70% of furniture failures are attributed to inadequate fastening methods. This staggering statistic underlines the importance of selecting the correct furniture fasteners that not only meet the project requirements but also withstand daily use. As industry expert Dr. Sarah Whittaker states, “The right fastener can enhance durability and improve the overall performance of the furniture, ensuring it stands the test of time.”

As we approach 2025, the market for innovative furniture fasteners is projected to grow by 12% annually, driven by advancements in materials and manufacturing techniques. Furniture designers and builders are increasingly recognizing that investing in quality fasteners is crucial for achieving longevity and safety in their creations. Additionally, sustainable options are gaining traction, reflecting a broader trend towards eco-friendly practices in the furniture industry. Thus, understanding the nuances of different types of furniture fasteners—from screws and dowels to specialty connectors—becomes imperative for anyone looking to undertake new furniture projects effectively.

Understanding the Different Types of Furniture Fasteners Available

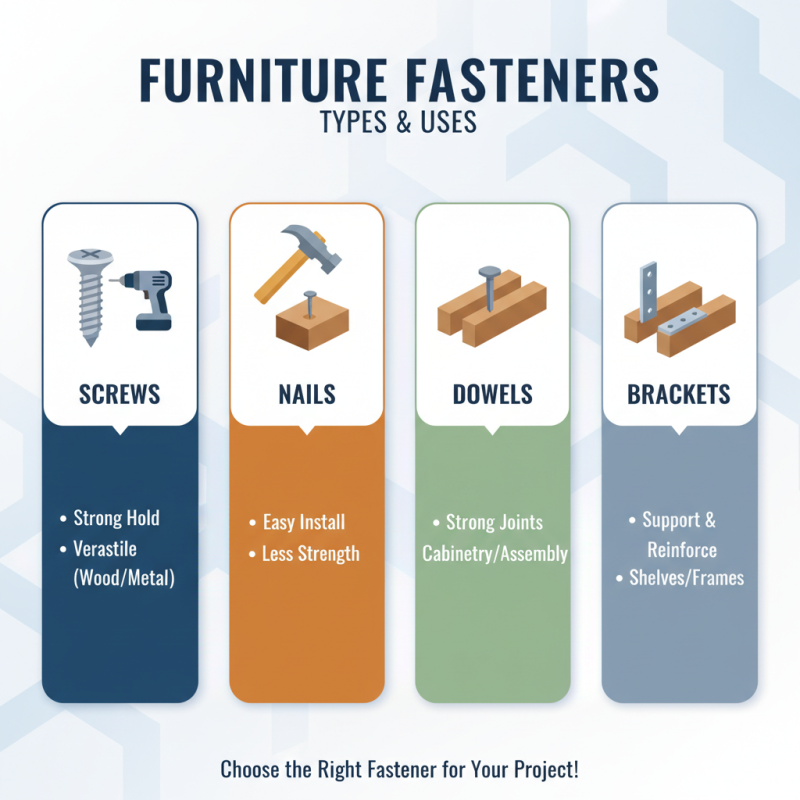

When it comes to selecting the right furniture fasteners for your projects, understanding the different types available is essential. Fasteners come in various forms, each designed for specific applications and materials. Common types include screws, nails, dowels, and brackets. Screws, often preferred for their strong hold, are versatile and can be used in various wood types, while nails are generally easier to install but may not provide the same level of strength. Dowels, which are cylindrical wooden rods, are perfect for creating strong joints, especially in cabinetry and furniture assembly.

Brackets and hinges also play a crucial role in furniture construction, allowing for improved stability and movement in projects like tables and cabinets. When choosing fasteners, consider the material you are working with and the intended use of the furniture. For instance, if you’re building outdoor furniture, selecting rust-resistant fasteners will ensure longevity. Moreover, the choice of fastener affects not only the structural integrity of the piece but also its aesthetic. Properly selected fasteners will enhance both durability and the appearance of your furniture, making it essential to understand each type and its specific applications.

Key Factors to Consider When Choosing Furniture Fasteners

When selecting furniture fasteners for your projects, it's crucial to consider several key factors that can significantly affect the durability and functionality of your final piece. One of the most important aspects is the material of the fasteners. Options such as wood screws, metal bolts, and dowels each offer distinct benefits. For instance, wood screws provide strong hold and are versatile for various wood types, while metal fasteners can offer superior strength for heavier items.

Another essential factor is the size and length of the fasteners. Choosing the right size ensures that the fasteners provide adequate support without splitting the material. A general rule of thumb is that the length should be at least 1.5 times the thickness of the material being joined.

**Tips:** Always pre-drill holes for screws to avoid damaging the wood and to ensure a secure fit. Additionally, consider using fasteners with coatings that resist corrosion if your furniture will be exposed to moisture. Lastly, think about the type of joint you are creating; for instance, pocket screws may be ideal for concealed joints, providing a clean aesthetic while maintaining strong connections.

2025 Guide: How to Choose the Best Furniture Fasteners for Your Projects

| Fastener Type | Material | Load Capacity (lbs) | Corrosion Resistance | Recommended Use | Installation Difficulty |

|---|---|---|---|---|---|

| Wood Screws | Steel | 200 | Low | Join wooden components | Easy |

| Dowels | Beech Wood | 150 | None | Edge-to-edge joints | Moderate |

| Pocket Holes | Aluminum | 250 | High | Hidden joints | Easy |

| Nails | Steel | 100 | Low | Quick assembly | Easy |

| Brackets | Stainless Steel | 400 | High | Structural support | Moderate |

Comparing Material Strength and Durability of Fasteners

When choosing the best furniture fasteners for your projects, understanding the material strength and durability is crucial. Fasteners come in various materials, including steel, aluminum, plastic, and brass, each offering unique benefits. Steel fasteners are known for their exceptional tensile strength, often exceeding 1,200 MPa, making them ideal for heavy-load applications. According to a report from the American Institute of Steel Construction, steel fasteners maintain structural integrity even under significant stress, which is vital for furniture that experiences frequent use or weight variations.

On the other hand, aluminum fasteners, with a tensile strength ranging from 200 to 400 MPa, provide a lightweight alternative without compromising too much on durability. Their corrosion resistance adds longevity, particularly in environments prone to moisture. Furthermore, research from the Wood Products Council highlights the increasing popularity of non-metal fasteners, such as plastics, which can be engineered for specific applications. Though they may have lower strength ratings, typically around 30 to 80 MPa, they still serve well in lighter applications and can be beneficial given their non-corrosive nature.

Durability also varies significantly among fastener materials, affected not only by tensile strength but also by factors like environmental exposure and material fatigue. A study conducted by the Fastener Quality Act indicates that while high-strength steel fasteners exhibit fatigue resistance in repetitive load situations, their performance can diminish in corrosive settings, necessitating coatings or higher-grade materials. As such, the choice of fasteners should align with the specific requirements of the furniture's intended use and environment.

2025 Guide: Comparison of Furniture Fasteners Material Strength and Durability

Application Guidelines for Various Furniture Projects

When selecting furniture fasteners for your projects, understanding the specific application guidelines is crucial. Different furniture types require different fastening methods to ensure stability and durability. For instance, when constructing wooden furniture, wood screws are often the go-to option as they provide strong holding power. Be sure to choose screws that match the thickness of your wood to avoid splitting. Additionally, using pilot holes can enhance precision and prevent damage to your materials.

For upholstery projects, staples and tacks are fundamental for securing fabric to frames. Opt for heavy-duty staples for thicker materials, which will withstand wear and tear better over time. When using tacks, make sure they are long enough to penetrate the frame adequately, providing a secure hold without compromising the aesthetic appeal of your furniture.

**Tips:** Always pre-drill holes before inserting screws to prevent cracking, especially in hardwoods. If you're working with softer woods, consider using adhesive along with fasteners for added strength. Lastly, always assess the load expectations of your furniture; heavier pieces may require more robust fasteners to ensure safety and longevity.

Maintenance Tips for Prolonging the Life of Furniture Fasteners

When it comes to maintaining furniture fasteners, good practices can significantly extend their lifespan and ensure your furniture remains sturdy and reliable. According to a report from the Furniture and Home Improvement Industry, nearly 25% of furniture failures are attributed to fastener issues, highlighting the importance of proper maintenance. Regular inspection of screws, bolts, and other fasteners can help identify signs of wear or corrosion early, allowing for timely replacements before they compromise the integrity of the furniture.

Additionally, applying the right lubricants to threaded fasteners can improve their functionality and resistance to wear. Research suggests that nearly 30% of fastener-related problems arise due to improper lubrication, which can lead to galling or seizing over time. Using a silicone-based lubricant can enhance the mobility of fasteners in wooden furniture, while a light oil may be more suitable for metal components. Moreover, ensuring that the environment around the furniture is suitable—avoiding excessive humidity or extreme temperatures—can prevent rust and decay, thereby prolonging the effective life of fasteners. By following these simple maintenance tips, you can greatly contribute to the durability and performance of your furniture projects.

Related Posts

-

Revolutionizing Home Assembly: The Essential Role of Furniture Fasteners Explained

-

Understanding the Versatility of Carriage Bolts: Essential Guide for DIY Enthusiasts

-

How to Choose and Use Mushroom Head Screws: A Complete Guide

-

Innovative Trends in Truss Head Carriage Bolt Industry at 2025 China Import and Export Fair

-

5 Essential Tips for Choosing the Right Truss Head Carriage Bolt for Your Project

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project